Aluminum Sheet For Manufacture of Caps

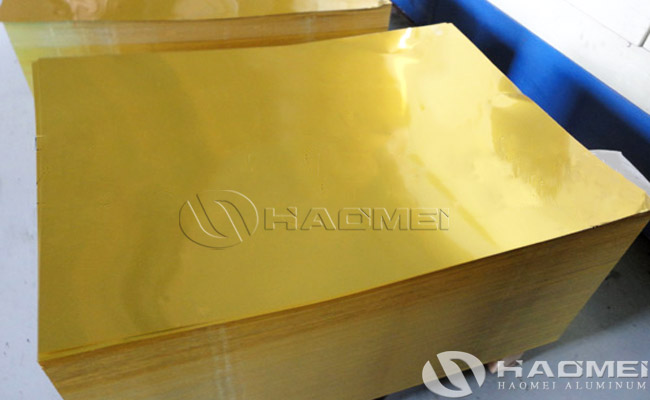

Aluminum sheet for the manufacture of caps are mainly used in the packaging of alcoholic beverages, food and beverages, cosmetics, and other products related to consumption. The aluminum bottle cap materials used in these applications have high requirements for product quality, so it is necessary for the industry to choose trustworthy manufacturers to purchase high quality aluminum sheet for caps materials. The aluminum sheet for bottle cap materials mainly use 1xxx, 3xxx, and 8xxx series of aluminum alloy sheets, the thickness ranges from 0.15 to 0.5mm. Although many manufacturers can produce these products, there are few truly safe and high-quality products.

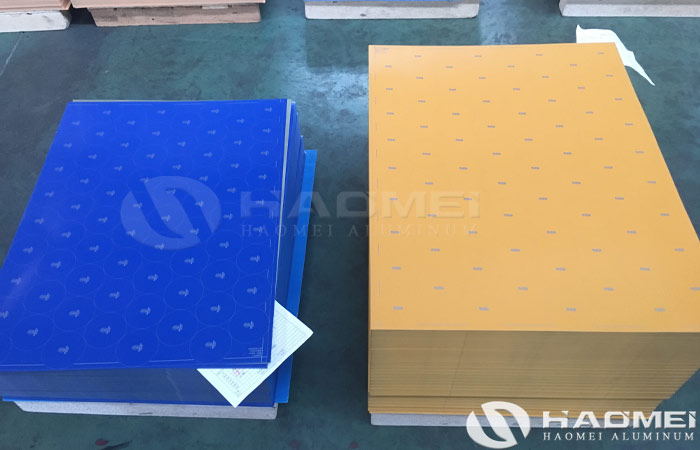

The pharmaceutical bottle caps are made of 8011 aluminum sheet for caps, used to seal the end of infusion bottles, providing good sealing performance. The 5182 aluminum sheet for cap materials are mainly used for can tops. The 5000 series aluminum alloy added magnesium element, making its hardness slightly better than other alloys. It solves the problem of deformation caused by impact during transportation and ensures the aesthetics of the can top. In addition, the 3000 series 3105 aluminum sheet for caps is mainly used for cosmetic bottle caps. Manufacturers put effort into the appearance, creating different shapes, applying bright colors, and making elaborate designs. It is also a good choice for high-end cosmetics.

What are the advantages of bottle closures that made by aluminum sheet for the manufacture of caps?

1. The aluminum caps are made of high-quality aluminum materials, which are hygienic and rust-free. They are easy to open without auxiliary tools. After opening, the caps are destructible, effectively preventing tampering.

2. Aluminum bottle cap materials have good cushioning, shock resistance, heat insulation, moisture resistance, and chemical corrosion resistance. They are non-toxic, non-absorbent, non-dusty, non-peeling, and provide good sealing performance.

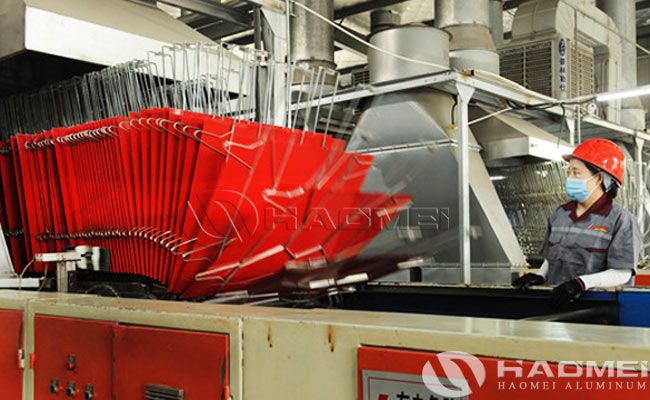

3. Aluminum caps can be made to be heat-resistant, water resistant, and resistant to alcohols based on customer requirements. The design can include color printing, embossed characters, and milling characters.

4.The inner liner of the aluminum bottle cap uses special adhesive dripping materials and advanced production processes to ensure excellent sealing performance after sealing the bottle. The surface of the cap has a larger flat area, making various printed texts, logos, and bottle caps more beautiful. It also enhances the value of your products.