Haomei Aluminum offer DOS lubricated aluminum for PP caps 3105/8011 with better anti-rust performance and deep drawing effect.

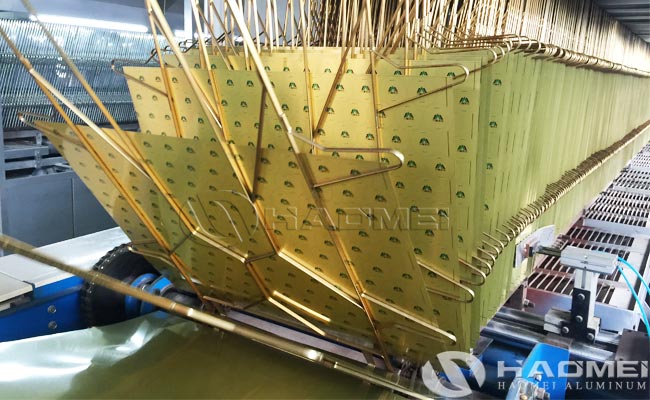

DOS oil is manufactured by the esterification of 2 saturated fatty acid (Sebaic Acid) and 2- ethylhexyl alcohol. It is a light yellow liquid and insoluble in water. DOS oil is coated widely by electrostatic oiler for lubrication of aluminum sheet/coil /foil for making closure caps ect.

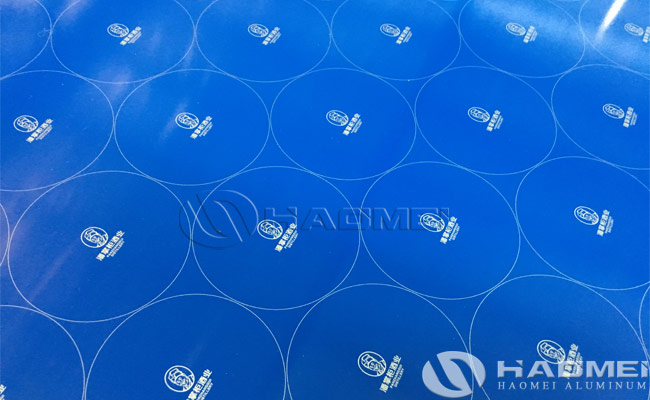

Too much or less Dos oil is not good for quality control, Haomei Aluminum's DOS oil coating production line has a good control of oil output and aluminum sheet shape when winding. The tiny charged oil particles move and uniformly absorbed on the surface of the aluminum sheet under effects of the high-voltage electric field, and accordingly achieving the purpose of coating the DOS oil on the surface of the aluminum sheet. Therefore, Haomei Aluminum DOS oil lubricatd aluminum sheet for bottle cap can fully meet quality requirements.

The Specification of DOS Chromized Aluminium For Bottle Cap:

Product Name | Chromized and DOS Treated Aluminium Sheet |

Alloy | 8011/3105 Aluminum Alloy |

Temper | H14, H16, H18, H24, H26, H44, H46 |

Thickness | 0.15-0.45mm |

Type | Sheet/Coils/Foils/Strips |

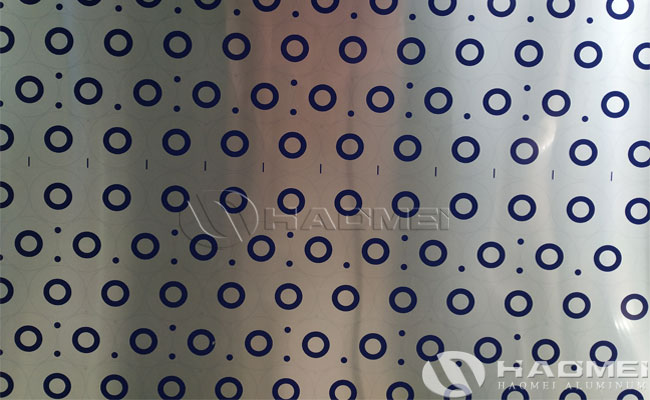

Surface Treatment | Aluminum surface is treated by phosphorous chromate and DOS oil treated. |

Application | Caps, closures and vials for the pharmaceutical industry. Closures ‘pilfer proof’ for the pharmaceutical industry. Lids and containers for the cosmetics industry. |

MOQ | 1-3 ton per specification |

Packaging | Export wooden stronger boxes |

Delivery Time | 25-30 days |

The Performance of DOS Lubricated Aluminum For PP caps:

1. Food grade certificate, it is unhazardous products registered FDA and passed oral toxicity test.

2. It has excellent inherent biodegradability and is useful for environmentally sensitive applications.

3. It can be removed by mineral solvent and alkaline cleaning oil quickly.

4. It has good lubricity and help to forming.

The Properties of Dos Oil Coated Aluminum For PP Caps:

Mechanical Property for CC Materials of Aluminium Sheet for PP Cap | ||||||

Alloy | Temper | Thickness (mm) | U.T.S (Mpa) | Elongation (%) | Earring Rate | |

8011 | H14 | 0.16~0.23 | 185~205 | >=2 | <2% | |

Mechanical Property for DC Materials of Aluminium Sheet for PP Cap | ||||||

Alloy | Temper | Thickness (mm) | U.T.S (Mpa) | Elongation (%) | Earring Rate | |

8011 | H14 | 0.16~0.23 | 125~155 | >=2 | <2% | |

The Advantages of DOS Treated Aluminum For Closure Caps:

1, Stable mechanical properties and good earing , less than 2% steadily or no ears for parts.

2, Good plasticity capable of drawing deepth, at most 75mm, free of "orange peel" after stamping.

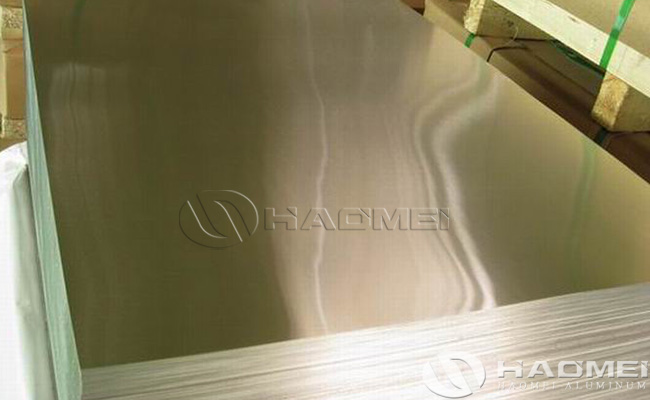

3, Better surface quality and uniform fine lines.

4, High thickness precision, up to +0.005mm.

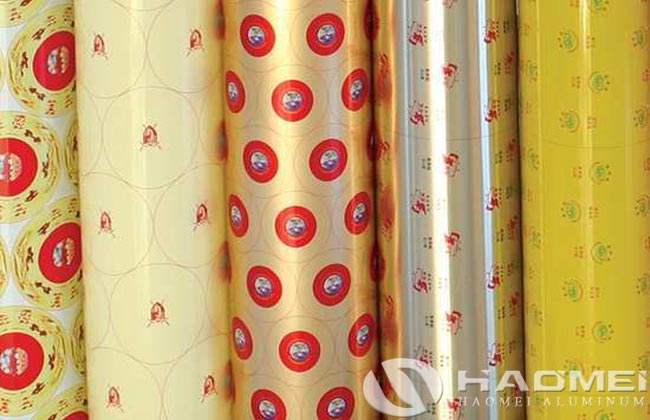

The Application of Chromized and Dos Treated Aluminium For Caps:

Bottle cap, such as ROPP, alcohol/ wine screw caps, beverages Omnia jar caps, pull-off caps, oral liquid, injection vial seals, etc.

The cap material process has to go through a number of processes such as hot rolling - cold rolling - annealing - dos oil lubrication -coating - printing- slitting - quality check- packaging, etc.

Wine bottle caps, medical caps, cosmetic caps, soft drink/juice/isotonic/energy beverage caps, cosmetic caps, can caps, vial seals caps, tear off seal caps, flip-off vial seals, aluminium closures, pharmaceutical caps, pull-off aluminum cap, injection vial caps, injection bottle caps.

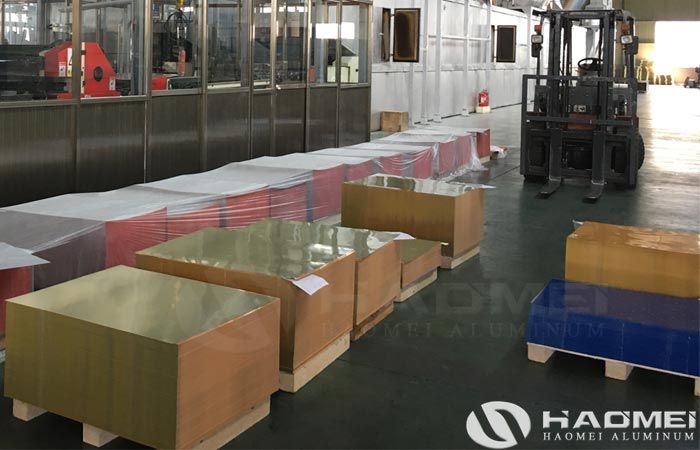

8011/3105 aluminum sheet will be packed by wooden pallet with net weight 0.8-1 ton per each pallet.There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

20’ GP FCL can full-load 20 tons by putting 2 layers of pallets of products.