8011 H14 Lacquer Aluminum Coil For Caps

8011 H14 lacquered aluminum coil for caps is the preferred material for bottle cap manufacturing, especially for scenes requiring high temperature sterilization resistance and high-precision printing. So we can see many long neck pp caps, ropp caps, screw caps and other types of aluminum caps made form 8011 h14 bottle caps material.

Product characteristics and technical requirements

- Alloy and temper: 8011 aluminum alloy, H14 temper (semi-hard state), with good deep drawing performance, low earing rate (<3%) and moderate tensile strength (135~165MPa), suitable for bottle cap stamping.

- Surface treatment: Color coating process usually includes epoxy coating (FDA certified) or color printing coating, which meets the requirements of high temperature sterilization resistance (such as 121℃ steam sterilization for 30 minutes or 180℃ baking for 90 minutes) and corrosion resistance. The product surface can reach Grade A of water brushing test after alkaline washing, which is suitable for multi-color printing.

- Dimensions:

Thickness: 0.15~0.3mm (tolerance ±0.005mm)

Width: 26~1200mm or 330~1000mm

Coil diameter: 300~1500mm, inner diameter of coil 76/152mm.

Application advantages of 8011 h14 lacquer aluminum coil for caps including:

- Excellent forming performance

8011 H14 aluminum for caps has good deep drawing performance and low earing rate, suitable for the processing of complex shape bottle caps, and the surface is flat and burr-free after forming.

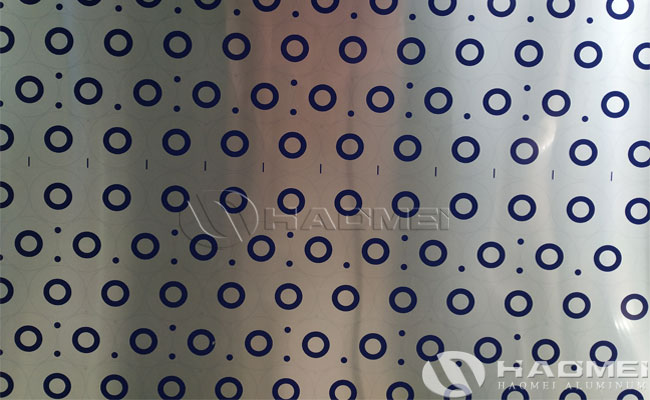

- Strong decorative effect

The color coating process can realize customization of various colors and patterns to meet the personalized needs of brands and enhance the added value of products.

- Safe and environmentally friendly

Aluminum meets food-grade safety standards, and the coating material is non-toxic and harmless, suitable for packaging in food, beverage, medicine and other industries.

- High cost-effectiveness

Aluminum coils are light in weight and easy to process, which can reduce production energy consumption and transportation costs; the color coating process replaces traditional printing, reducing production links and costs.

Application areas of 8011 h14 lacquered aluminum coil for caps

Mainly used for bottle cap sealing in the pharmaceutical, alcohol, cosmetics and other industries, such as:

- Medicinal bottle caps: need to be resistant to high pressure sterilization, moisture-proof and pollution-proof, and meet the strict standards of pharmaceutical packaging.

- Alcohol and beverage caps: require high sealing and anti-counterfeiting functions. Mingtai Aluminum has a market share of 60%~70% in alcohol cap materials.

8011 H14 lacquer aluminum coils for caps are particularly suitable for the manufacture of various bottle caps. This material combines the advantages of 8011 alloy with the additional protection and aesthetic effects brought by color coating technology, and is very suitable for high-end markets or application scenarios with special requirements for product appearance.