8011 H14 Aluminum Sheet For Closure Caps

8011 h14 aluminum sheet for closure caps is a specific aluminum alloy material that is specially used for manufacturing bottle caps. Together with 3105 h18 aluminum sheet, they two are the most common used aluminum sheet product for making closure caps for wine, cosmetic, beverage bottles.

8011 h14 aluminum sheet for closure caps has the following features and advantages:

Composition and Properties:

8011 aluminum sheet alloy is a medium strength alloy containing mainly aluminum and small amounts of other elements such as iron, silicon and copper. The addition of these elements is intended to improve the mechanical properties, corrosion resistance, and machinability of the aluminum sheet. The H14 temper indicates that the 8011 aluminum sheet has undergone a work-hardening treatment, which provides high strength and hardness, but also maintains a certain degree of ductility, this also benefit for making closure caps.

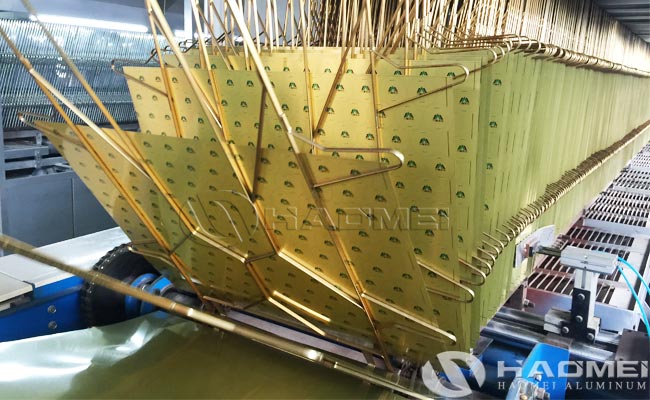

Surface treatment:

DC/CC refers to the cooling method of the aluminum for closuer caps 8011, where DC stands for direct castling and CC stands for continuous casting. This type of casting helps to optimize the microstructure of the 8011 h14 aluminum sheet and improve its surface quality and corrosion resistance. For cap manufacturing, a good surface finish ensures the aesthetics and sealing performance of the cap.

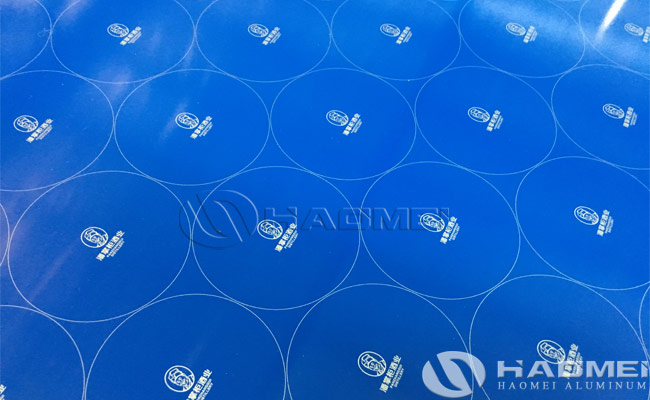

Bottle cap applications:

8011 H14 aluminum sheet is widely used in bottle cap manufacturing due to its good ductility, formability and sealing properties. It can be easily processed into various shapes and sizes to meet the needs of different bottle types. Meanwhile, the corrosion resistance of 8011 aluminum sheet also ensures that the bottle caps are not easy to rust or deform during long time use.

In conclusion, 8011 h14 aluminum sheet for closure caps is a high-quality bottle cap material with excellent mechanical properties, surface treatment effect and corrosion resistance, providing a reliable material guarantee for bottle cap manufacturing.