Haomei Aluminum's aluminium sheet for pilfer proof caps comply with US FDA and European directives regarding to use of aluminum which comes into contact with food, drinks, cosmetics and pharmaceuticals.

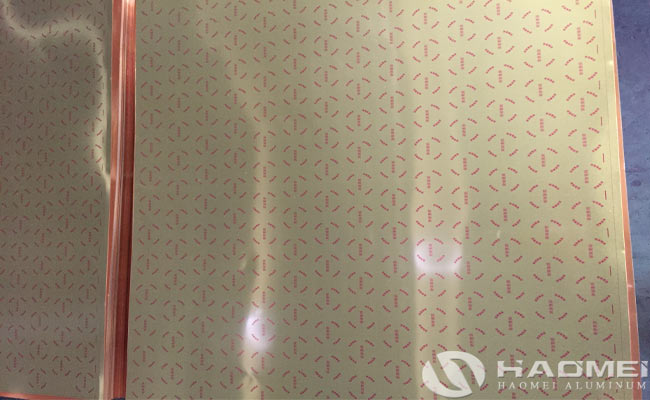

With experienced technical engineers and superb rolling technology, our aluminum sheet for caps are suitable for extremely deep drawn and highly decorated closures. By using our products, our closure makers clients could achieve a wide variety of painted finishes in their market and we have an excellent reputation as their reliable, flexible and innovative partner.

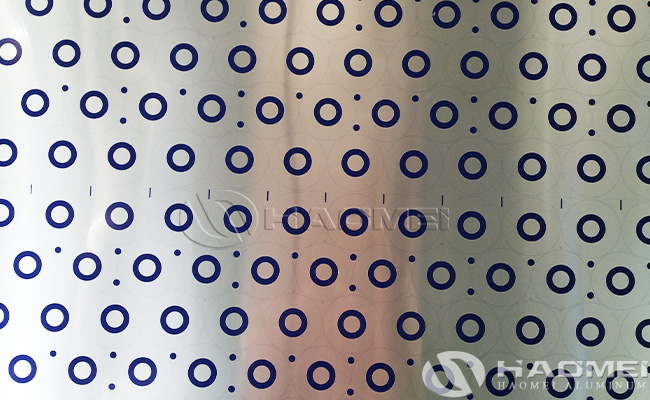

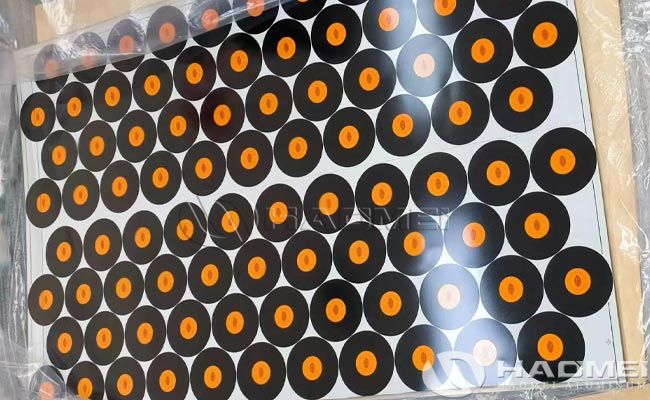

The aluminum pilfer proof cap has a simple structure, strong adaptability and good sealing effect. In addition, it can have rich patterns and realize mass production.

The Specification of Aluminium Sheet For Pilfer Proof Cap:

Alloy | 8011/3105 Aluminum Alloy |

Temper | H14, H16, H18, H24, H26, H44, H46 |

Thickness | 0.15-0.45mm |

Type | Sheet/Coils/Foils/Strips |

Surface Treatment | Aluminum surface is treated by phosphorous chromate and DOS oil treated. |

Application | Caps, closures and vials for the pharmaceutical industry. Closures ‘pilfer proof’ for the pharmaceutical industry. Lids and containers for the cosmetics industry. |

MOQ | 1-3 ton per specification |

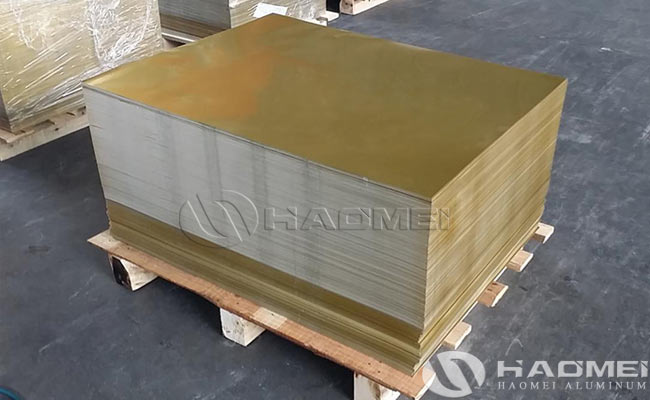

Packaging | Export wooden stronger boxes |

Delivery Time | 25-30 days |

Chemical Composition of 8011 3105 Chromized and Dos Treated Aluminium Sheet For Pilfer Proof Cap (%)

Alloy | Fe | Si | Cu | Mn | Mg | Cr | Zn | Ni | Ti | Other | Al |

8011 | 0.60~1.0 | 0.50~0.9 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | - | 0.08 | 0.15 | Remain |

3105 | 0.7 | 0.6 | 0.3 | 0.3~0.8 | 0.2~0.8 | 0.2 | 0.4 | - | 0.1 | 0.15 | Remain |

The Properties of Aluminium For Pilfer Proof Cap:

Mechanical Property for CC Materials of Aluminium Sheet for Pilfer Proof Cap | ||||||

Alloy | Temper | Thickness (mm) | U.T.S (Mpa) | Elongation (%) | Earring Rate | |

8011 | H14 | 0.16~0.23 | 185~205 | >=2 | <2% | |

Mechanical Property for DC Materials of Aluminium Sheet for Pilfer Proof Cap | ||||||

Alloy | Temper | Thickness (mm) | U.T.S (Mpa) | Elongation (%) | Earring Rate | |

8011 | H14 | 0.16~0.23 | 125~155 | >=2 | <2% | |

The Advantages of Aluminium Sheet For PilferProof Cap:

1, Stable mechanical properties and good earing , less than 2% steadily or no ears for parts.

2, Good plasticity capable of drawing deepth, at most 75mm, free of "orange peel" after stamping.

3, Better surface quality and uniform fine lines.

4, High thickness precision, up to +0.005mm.

The Application of Aluminum Sheet For Pilfer Proof Cap:

Aluminium sheet and coil for the Pilfer Proof cap market. Customers use our aluminum sheet to manufacture the caps for long neck wine bottles, plus a range of pilfer proof caps for beverage bottles, soft drinks, juice, isotonic beverage, energy beverage, and other products.

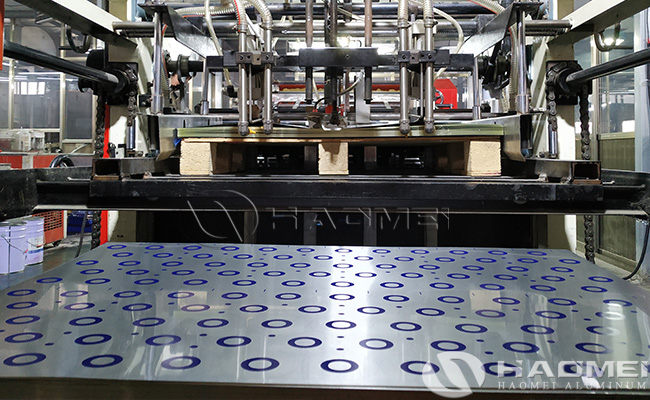

The cap material process has to go through a number of processes such as hot rolling - cold rolling - annealing - dos oil lubrication -coating - printing- slitting - quality check- packaging, etc.

Wine bottle caps, medical caps, cosmetic caps, soft drink/juice/isotonic/energy beverage caps, cosmetic caps, can caps, vial seals caps, tear off seal caps, flip-off vial seals, aluminium closures, pharmaceutical caps, pull-off aluminum cap, injection vial caps, injection bottle caps.

8011/3105 aluminum sheet will be packed by wooden pallet with net weight 0.8-1 ton per each pallet.There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

20’ GP FCL can full-load 20 tons by putting 2 layers of pallets of products.