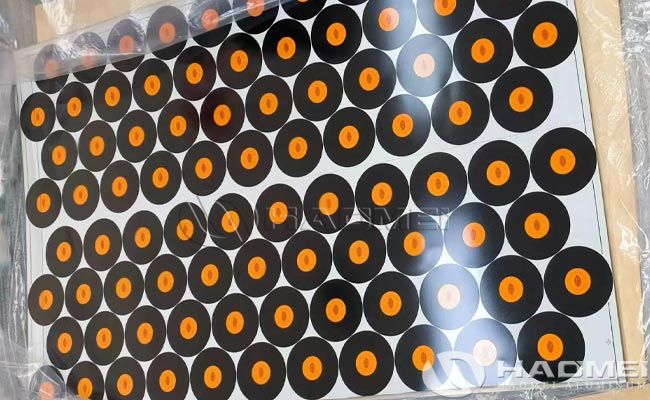

Color Printed Aluminum Sheet For Bottle Cap 3105 8011

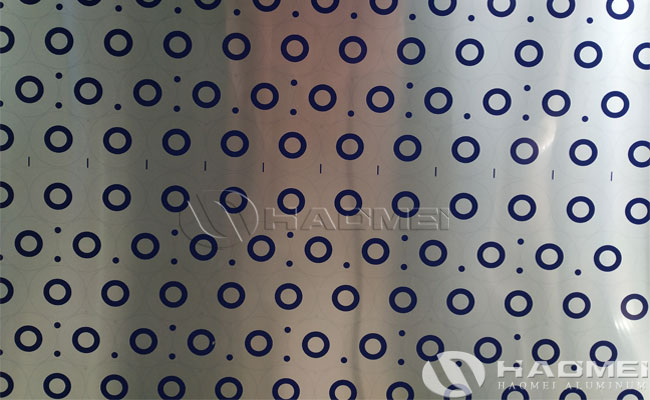

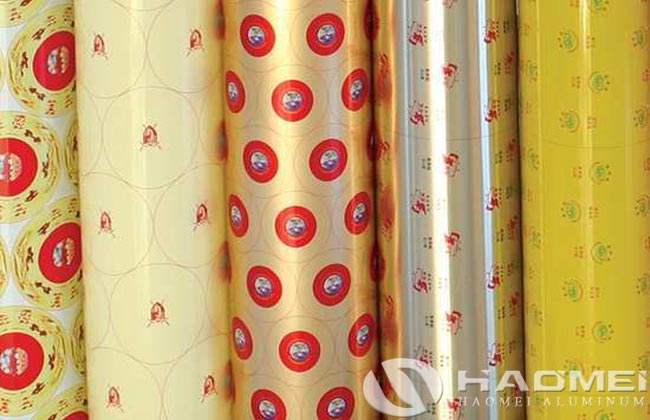

Color printed aluminum sheet for bottle cap 3105 8011 are usually used to make packaging materials such as pp caps and ropp caps. This type of aluminum sheet is not only used to make bottle caps, but is also widely used in anti-counterfeiting and anti-theft caps, plastic caps, aluminum-plastic combined caps and other fields. 3105 and 8011 are two common printed aluminum sheet materials for making bottle caps, they have superior performance, small earing rate, good elongation performance, and strong coating adhesion after surface treatment. They are suitable for printing and painting, and can achieve high-quality printing effects. They are the best raw materials for making bottle caps, medicine caps and other products. The specifications of aluminum sheet for bottle caps are complete, the patterns are clear and beautiful, and 1-6 colors can be printed at one time, further improving the beauty of the product.

The production process of color printed aluminum sheet for bottle cap 3105 8011 is as follows:

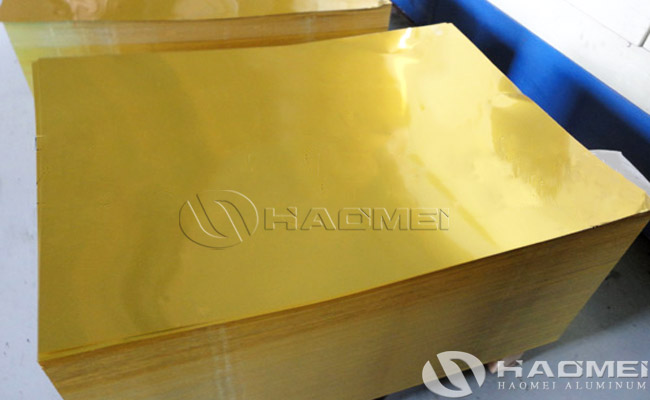

1. Aluminum sheet preparation: First, select high-quality aluminum alloy materials, and after surface treatment and cleaning, ensure that the surface is flat and smooth, without impurities and stains.

2. Coating treatment: The aluminum sheet is coated, usually with a layer of primer to enhance the adhesion and corrosion resistance of the printing ink. The color of the primer can be selected according to actual needs.

3. Multi-color printing: The aluminum sheet is printed by a multi-color printing machine, and different colors and patterns are printed according to the design requirements. Flexographic printing or offset printing technology is usually used to ensure clear and accurate printing quality.

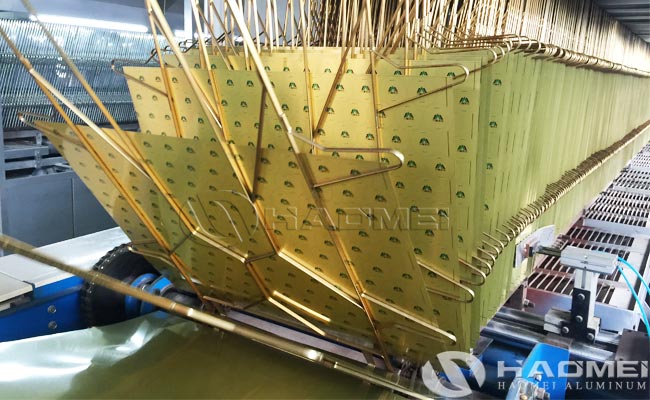

4. Drying and curing: After printing, the aluminum sheet needs to be dried and cured to ensure that the printing ink is firmly attached to the surface of the aluminum sheet and is wear-resistant and corrosion-resistant.

5. Cutting and molding: Finally, the printed aluminum sheet for pp caps is cut and molded to make packaging materials such as bottle caps. The shape and size of the cutting and molding are customized according to customer needs.

In general, color printed aluminum sheet for bottle cap 3105 8011 are both high-quality aluminum sheet materials for printing. They have good molding performance, corrosion resistance and printing performance. Through coating, printing, drying and curing, and cutting and molding process steps, bottle caps with rich patterns and colors are produced, which are widely used in packaging in food, beverage and other industries.