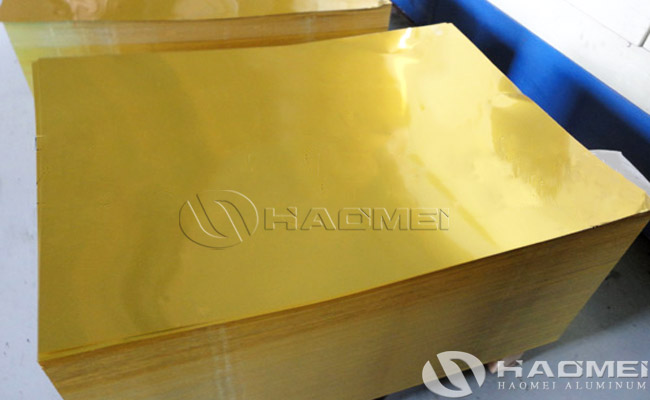

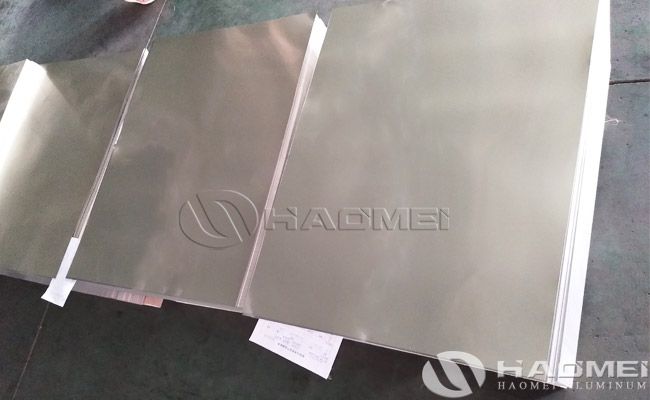

8011 aluminum for closure caps is mainly applied to stamping shallow caps, which can be cast and rolled. As for its quality, it should be of smooth surface, no obvious roll marks, no obvious defects such as oil stains, scratches, bright strips, etc. The earring rate should be less than 3%.

The process of aluminum for closure caps is cold rolling-foil rolling-straightening-slitting-packaging and other processes. It does not require annealing treatment, so the production period is the shortest and the price is relatively cheaper.

The Specification of Aluminum For Closures Caps 8011H14:

Alloy | 8011 Aluminum Alloy |

Temper | H14, H16, H24, H26, H44, H46 |

Thickness | 0.15-0.45mm |

Type | Sheet/Coils/Foils/Strips |

Surface Treatment | Aluminum surface is treated by phosphorous chromate and DOS oil treated. |

Application | Caps, closures and vials for the pharmaceutical industry. Closures ‘pilfer proof’ for the pharmaceutical industry. Lids and containers for the cosmetics industry. |

MOQ | 1-3 ton per specification |

Packaging | Export wooden stronger boxes |

Delivery Time | 25-30 days |

Properties of Aluminum Sheet For Closure AA8011:

Chemical Composition of Aluminum For Closure Caps 8011:

Alloy | Fe | Si | Cu | Mn | Mg | Cr | Zn | Ni | Ti | Other | Al |

8011 | 0.60~1.0 | 0.50~0.9 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | - | 0.08 | 0.15 | Remain |

Mechanical Property for Continuous Casting

Alloy | Temper | Thickness (mm) | U.T.S (Mpa) | Elongation (%) |

8011 | H14 | 0.16~0.23¡¡ | 185~205 | ¨R2 |

Mechanical Property for Direct Casting

Alloy | Temper | Thickness (mm) | U.T.S (Mpa) | Elongation (%) |

8011 | H14 | 0.16~0.23 | 125~155 | ¨R2 |

The Advantages of 8011 Aluminum For Closure Caps:

1, Stable mechanical properties and good earing , less than 2% steadily or no ears for parts.

2, Good plasticity capable of drawing deepth, at most 75mm,free of "orange peel" after stamping.

3, Better surface quality and uniform fine lines.

4, High thickness precision, up to +0.005mm.

The Application of 8011 Aluminum Closure Sheet For Caps:

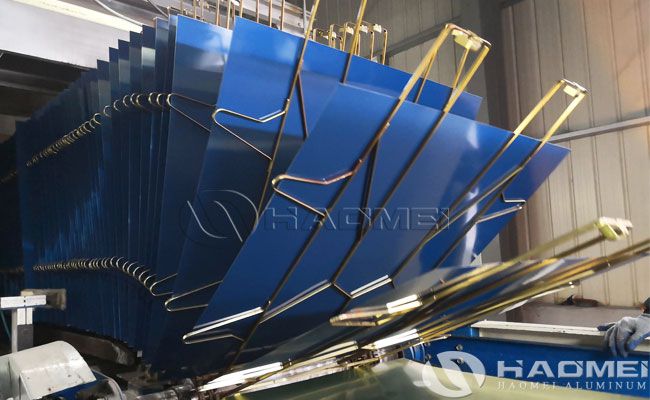

Wine bottle caps, medical caps, cosmetic caps, soft drink/juice/isotonic/energy beverage caps, cosmetic caps, can caps, vial seals caps, tear off seal caps, flip-off vial seals, aluminium closures, pharmaceutical caps, pull-off aluminum cap, injection vial caps, injection bottle caps.

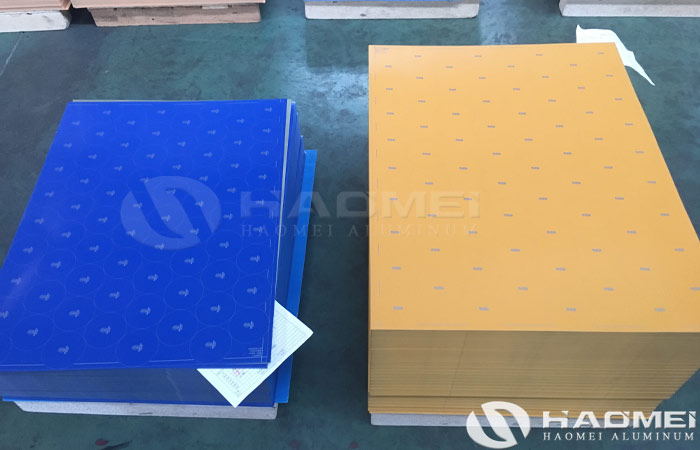

The cap material process has to go through a number of processes such as hot rolling - cold rolling - annealing - dos oil lubrication -coating - printing- slitting - quality check- packaging, etc.

Wine bottle caps, medical caps, cosmetic caps, soft drink/juice/isotonic/energy beverage caps, cosmetic caps, can caps, vial seals caps, tear off seal caps, flip-off vial seals, aluminium closures, pharmaceutical caps, pull-off aluminum cap, injection vial caps, injection bottle caps.

8011/3105 aluminum sheet will be packed by wooden pallet with net weight 0.8-1 ton per each pallet.There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

20’ GP FCL can full-load 20 tons by putting 2 layers of pallets of products.