Epoxy paint is very resistant to chipping, fading and peeling, it provides excellent protection against extreme temperatures, abrasions, and corrosive fluids.

Epoxy paint is made up of two parts: a primer coat and a top coat. The primer coat is usually white or light-colored, and it helps the top coat to adhere better to the surface. The top coat is the part of the epoxy paint that actually contains the color pigment. Once the two coats are mixed together, they form a bond that is incredibly strong and durable. This means that epoxy coated aluminum sheet for closure caps have a smoother, more professional appearance. In addition, epoxy paint provides superior protection against rust and corrosion.

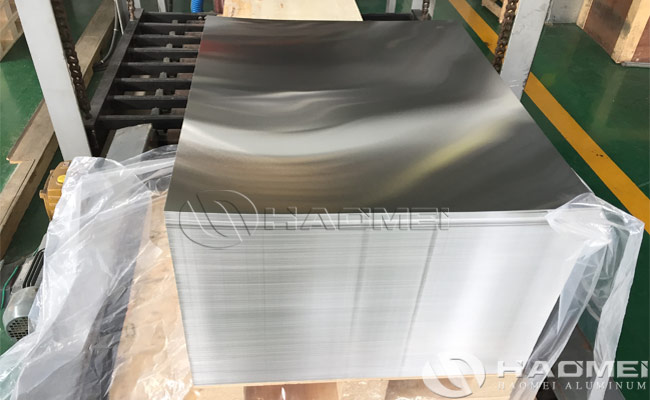

The Specification of Epoxy Paint Coated Aluminum Sheet For Closure Caps:

Product Name | Epoxy Paint Coated Aluminium Sheet |

Alloy | 8011/3105 Aluminum Alloy |

Temper | H14, H16, H18, H24, H26, H44, H46 |

Thickness | 0.15-0.45mm |

Type | Sheet/Coils/Foils/Strips |

Surface Treatment | Aluminum surface is treated by phosphorous chromate and DOS oil treated. |

Application | Caps, closures and vials for the pharmaceutical industry. Closures ‘pilfer proof’ for the pharmaceutical industry. Lids and containers for the cosmetics industry. |

MOQ | 1-3 ton per specification |

Packaging | Export wooden stronger boxes |

Delivery Time | 25-30 days |

The Performance of Epoxy Paint Coated Aluminum Sheet For PP Caps:

Specially formulated to be used on aluminum metal

Resistant to weather and rust

Highly durable

Quick-drying

Forms the perfect base for a wide variety of further applications

The Properties of Epoxy Paint Coated Aluminum Sheet For Caps:

Mechanical Property for CC Materials of Aluminium Sheet for Bottle Cap | ||||||

Alloy | Temper | Thickness (mm) | U.T.S (Mpa) | Elongation (%) | Earring Rate | |

8011 | H14 | 0.16~0.23 | 185~205 | >=2 | <2% | |

Mechanical Property for DC Materials of Aluminium Sheet for Bottle Cap | ||||||

Alloy | Temper | Thickness (mm) | U.T.S (Mpa) | Elongation (%) | Earring Rate | |

8011 | H14 | 0.16~0.23 | 125~155 | >=2 | <2% | |

The Advantages of Epoxy Paint Coated Aluminum For Closure Caps:

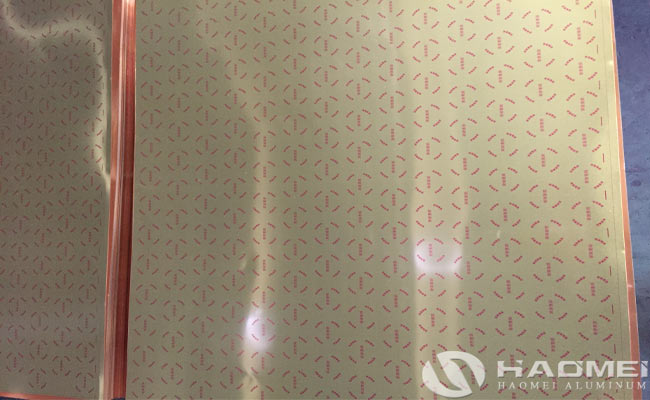

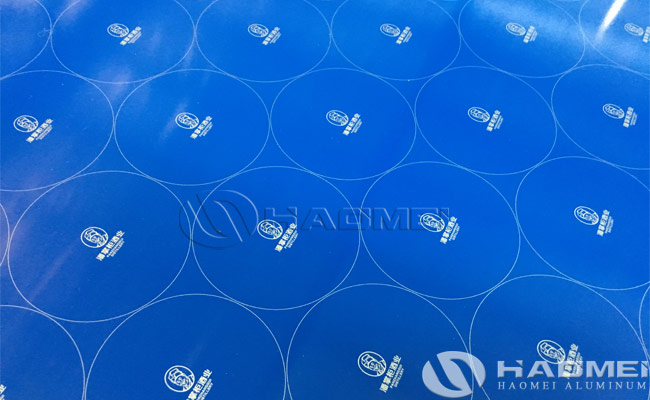

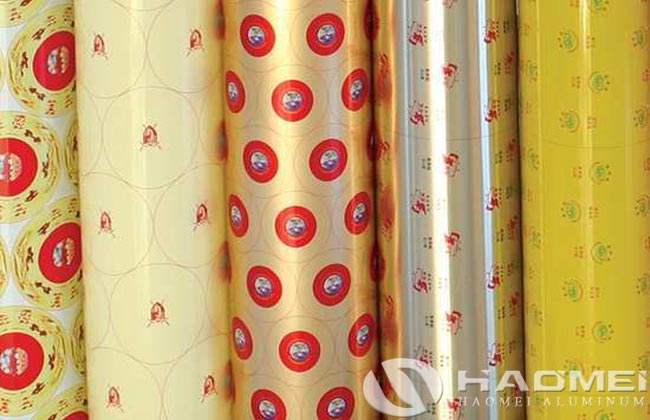

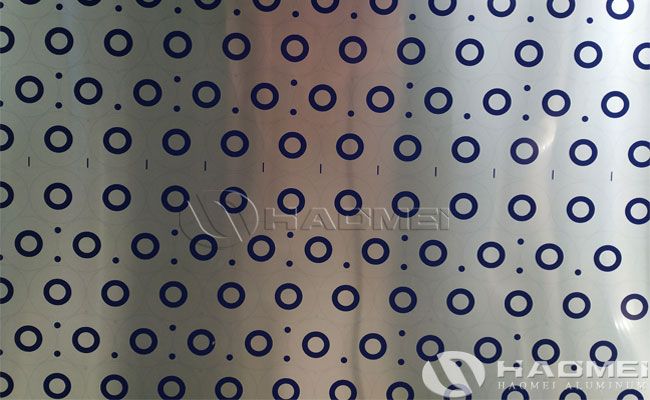

1) In complete sizes and sorts, with clear and beautiful pattern.

2) If applying fluorescence, change to different temperatures and composite anti-forging printing technique, the effect will be better.

3) High temperature resistant without any distortion and color change;

4) The paint won't peel off during production;

5) Tensile Strength: 145;

6) Yield Strength: 136-137;

7) Elongation: 2.0;

8) Earring Rate: <2%;

9) It's the best material for bottle caps;

10) Small order is acceptable

The Application of Epoxy Paint Coated Aluminum For PP Caps:

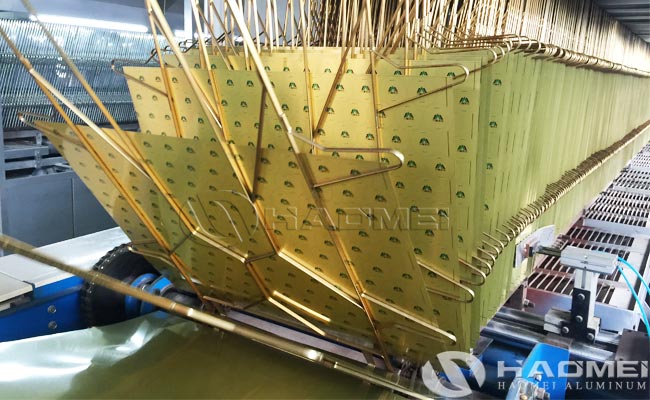

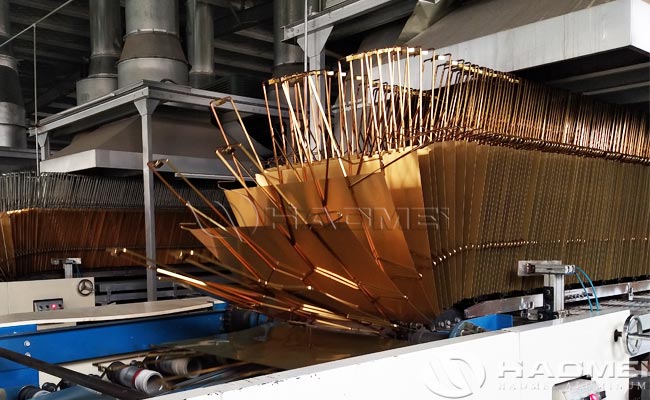

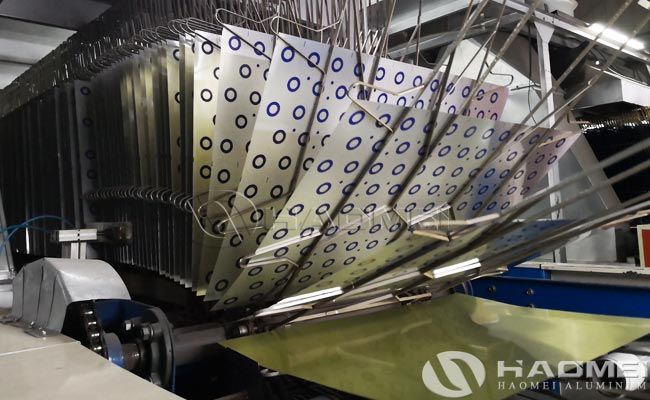

The cap material process has to go through a number of processes such as hot rolling - cold rolling - annealing - dos oil lubrication -coating - printing- slitting - quality check- packaging, etc.

Wine bottle caps, medical caps, cosmetic caps, soft drink/juice/isotonic/energy beverage caps, cosmetic caps, can caps, vial seals caps, tear off seal caps, flip-off vial seals, aluminium closures, pharmaceutical caps, pull-off aluminum cap, injection vial caps, injection bottle caps.

8011/3105 aluminum sheet will be packed by wooden pallet with net weight 0.8-1 ton per each pallet.There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

20’ GP FCL can full-load 20 tons by putting 2 layers of pallets of products.