Aluminum Sheets For Beverage Caps

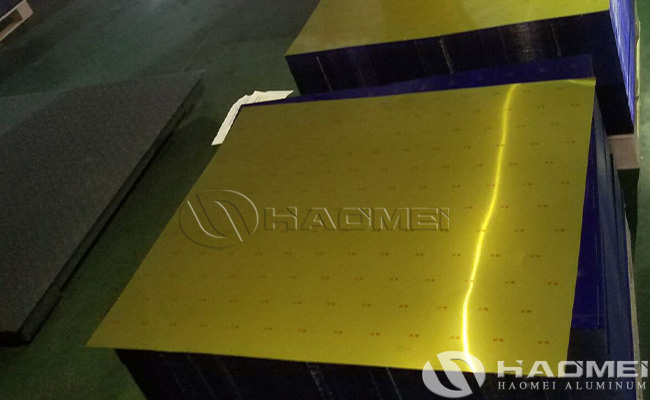

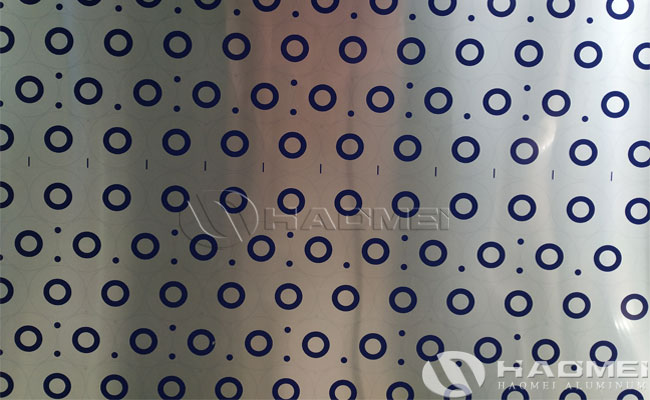

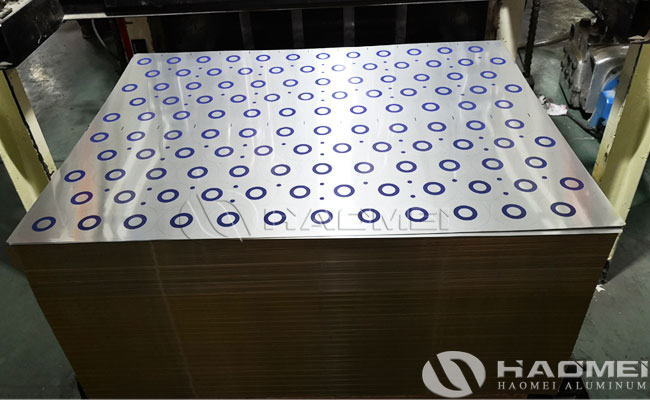

Aluminum sheets for beverage caps are widely used to seal glass bottles and cans of soft drinks and energy drinks. They can meet special requirements such as high-temperature cooking and sterilization, and have strong adaptability and good sealing effect. Aluminum sheet for beverage caps require high dimensional accuracy and good surface quality, The thickness tolerance is ±0.008~0.013mm, the surface roughness R a is 0.25±10 microns, and the flatness I is less than 6. In addition, high strength, uniform performance, and good formability are required. A layer of protective paint is applied on both sides of the aluminum sheet for caps to resist corrosion by strong acidic or alkaline substances.

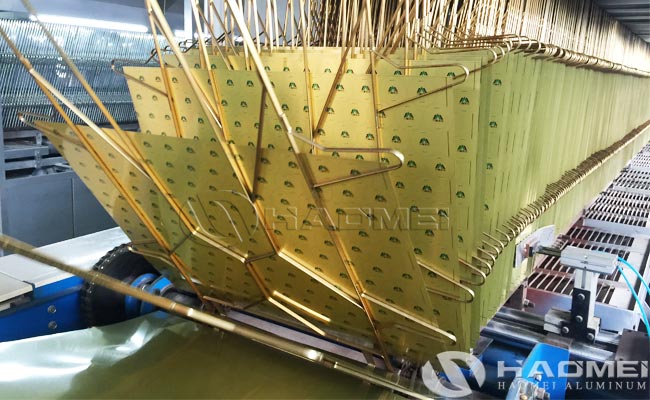

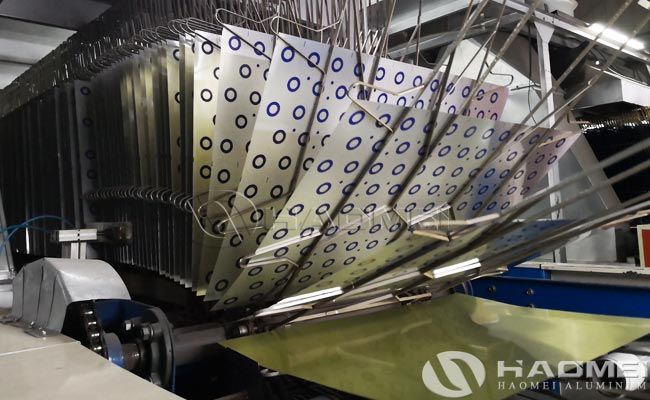

By adjusting the chemical composition, rolling amount and temperature, we increase the strength of the aluminum sheets for beverage caps material and can reduce the gauge (weight). In order to ensure the properties required by customers, such as "openness" and "selvage ratio", we produce aluminum sheet for caps materials through composition adjustment, rolling temperature/time, and annealing temperature control. Phosphate chromate treatment or zirconium treatment for improved adhesion to paint is also available upon request. Strictly control the flatness and verticality to prevent color fading, uneven color and printing misalignment during printing.

The thickness range of the aluminum sheets for beverage caps is 0.254~0.354 mm; the commonly used alloys and states of the beverage caps material are 8011-H19, 8011-H19 and 3105-H19, etc. The material for the caps varies with the beverage in the can. When the beverage in the can is coffee without internal pressure, use medium-strength 3105 H19; when the beverage in the can is a refreshing beverage with internal pressure (49 MPa) due to carbon dioxide, such as beer, use high-strength 8011-H19.