Aluminum Sheet For Wine Bottle Screw Caps

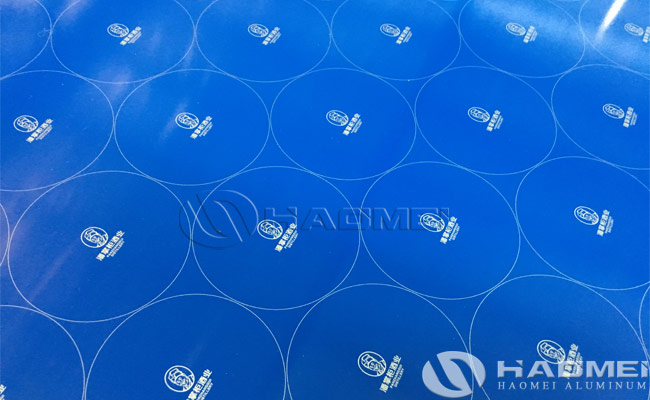

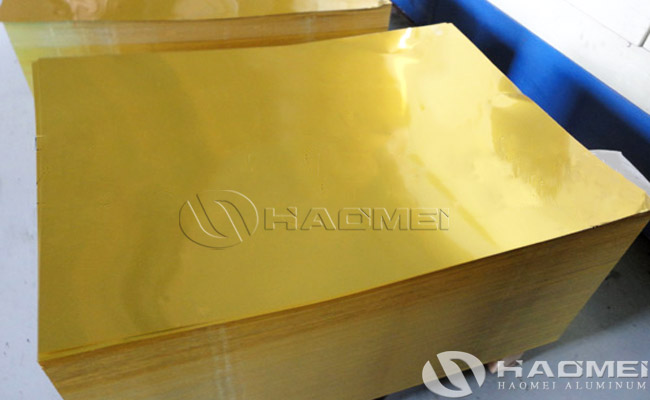

The main thickness of the 3105 aluminum sheet for wine bottle screw caps is 0.15-0.3mm, and the states are H12, H14, H16, etc. Metal is one of the materials used for bottle caps. Metal materials include aluminum, tin and steel. These metals have good corrosion resistance and sealing properties, effectively protecting the liquid inside the bottle from external influences. Different types and brands of wine bottle caps have different material choices, depending on specific needs and design requirements. At the same time, the production of wine bottle caps also needs to consider safety, hygiene, and environmental protection.

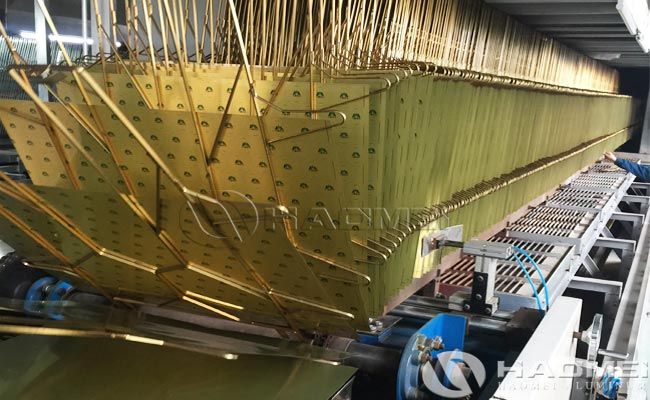

One of the processes in aluminum sheet for wine bottle screw caps is heat treatment, known as finished product heat treatment. This treatment includes annealing, solution treatment, quenching, natural aging, and artificial aging treatment. Currently, Haomei Aluminum also has grading aging and deformation heat treatment processes. Artificial aging treatment can provide mechanical properties of aluminum for wine bottle caps products, as well as enhance their stress corrosion resistance and fracture toughness.

Advantages of manufacturing aluminum sheet for wine bottle screw caps:

1. The aluminum sheet for wine bottle caps is made of high-quality aluminum material, which is hygienic, rust-proof, easy to open without the need for auxiliary tools. After opening, the cap is damaged, effectively preventing theft.

2. The aluminum sheet for wine bottle caps has good cushioning, shock resistance, heat insulation, moisture resistance, and chemical corrosion resistance. It is non-toxic, non-absorbent, does not produce dust, peeling, and flaking, and has excellent sealing performance.

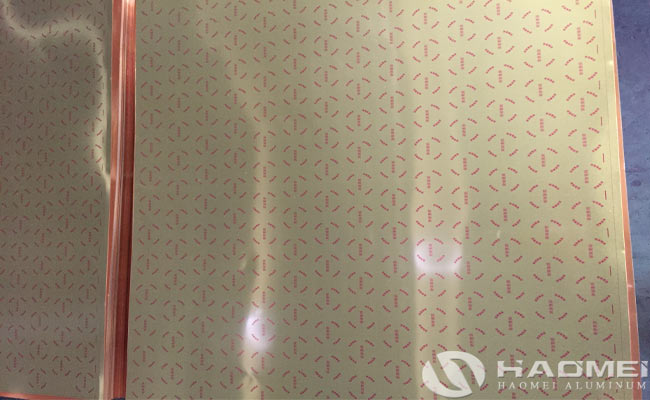

3. The aluminum cover made from the aluminum sheet for bottle caps can be made resistant to high temperatures, boiling water, and alcohol, etc., according to customer requirements. The design can be printed in colors, embossed, or milled.

4. The inner cushion of this cap is made of special drip glue material and advanced production technology, making it have excellent sealing performance after bottle sealing. The cap surface has a larger flatness, making various text and logo patterns printed on the cap more aesthetically pleasing, and making your product more valuable.