Aluminum For Bottle Caps

The commonly used aluminum for bottle caps are 8011 aluminum bottle cap material, 1070 aluminum bottle cap material, 1060 aluminum bottle cap material, 5052 pull cap material, and 3105 wine bottle cap material. These aluminum alloy for bottle caps have good deep drawing performance and low ear-making rate. After the cap making process, they also have a certain strength advantage after baking. 3105 aluminum sheet has good rust resistance and is suitable for making aluminum products such as bottle caps, beverage caps and cosmetic caps.

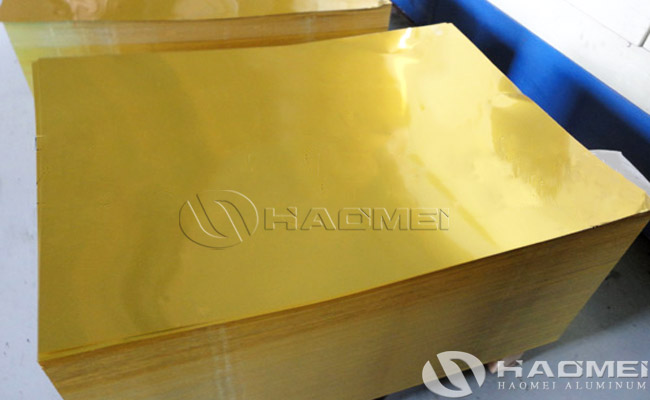

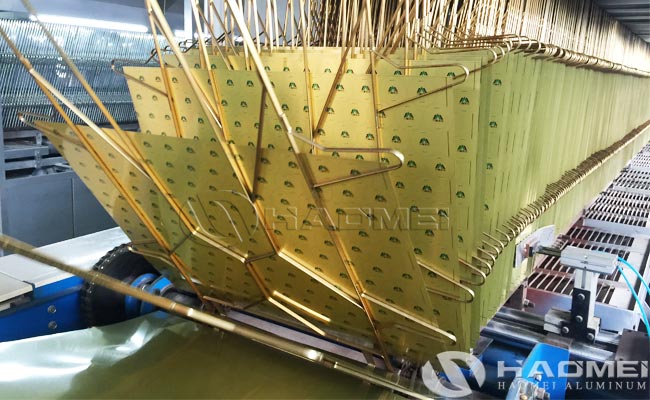

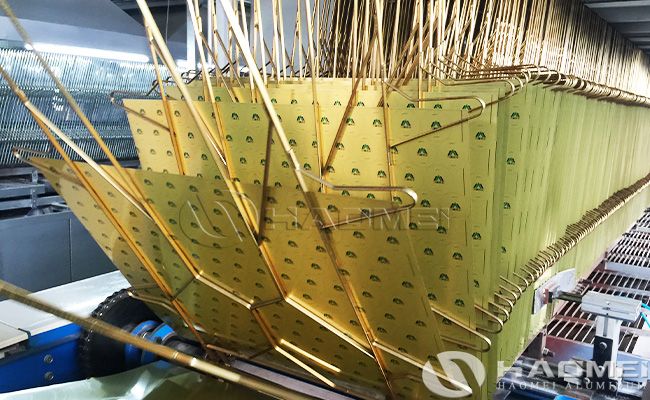

In terms of aluminum bottle caps and aluminum container caps, aluminum alloys with higher elongation rates are usually used, such as 3105 and 8011 aluminum sheets. This kind of aluminum for bottle caps belongs to the pure aluminum series, with good elongation rate and tensile strength, which can meet the requirements of conventional processing (stamping, stretching) and have high formability. Therefore, aluminum sheet for bottle caps is usually used as the raw material for aluminum pp closure caps. Since aluminum bottle caps are often processed on highly automated production lines, the strength, elongation rate, and dimensional deviation of the material are required to be very strict, otherwise cracking or folding marks may occur during deep drawing. To ensure easy printing after cap forming, the aluminium material for bottle cap material requires a flat surface without rolling marks, scratches and stains.

The product detailed of aluminum alloy for bottle caps offered by Haomei Aluminum are:

Alloy: 8011/3105

Temper: H14,H16,H26,H24

Thickness: 0.16-0.23mm

Width: 500-1000mm(sheet), 50-1500(strip)

Sheet length: 500-1500mm

Strip coil ID: 75,150,300,350,505mm

Application: pharmaceutical, cosmetic, screw caps, capsules, wine bottle caps

Surface: mill finish, lacquered, pre-painted, color printed etc.

<Tolerance>

Thickness: ±0.005mm

Width: +0.5 -0mm

Length: ±0.2mm

Diagonal: ≤1mm

The surface of the aluminum for bottle caps needs to undergo chromizing treatment to increase its corrosion resistance and aesthetics. At the same time, it can also improve its weather resistance and scratch resistance, avoiding problems such as oxidation, discoloration, and scratches during use.