Bottle cap aluminum sheet has high quality of drawability and lacquer adhesion, guaranteeing the highest quality printing of drawings and designs.

Haomei Aluminum produces a range of quality aluminum closure sheet alloys and tempers for a wide variety of bottle caps applications, from liquor, spirits and soft drinks to pharmaceutical packaging. We supplies aluminum sheet and coils for the manufacture of bottle caps. Applications range from screw caps for whiskey and other beverage bottles to aluminum cap for wine bottles.

The Specification of Bottle Cap Aluminum Sheet:

Alloy | 8011/3105 Aluminum Alloy |

Temper | H14, H16, H18, H24, H26, H44, H46 |

Thickness | 0.15-0.45mm |

Type | Sheet/Coils/Foils/Strips |

Surface Treatment | Aluminum surface is treated by phosphorous chromate and DOS oil treated. |

Application | Caps, closures and vials for the pharmaceutical industry. Closures ‘pilfer proof’ for the pharmaceutical industry. Lids and containers for the cosmetics industry. |

MOQ | 1-3 ton per specification |

Packaging | Export wooden stronger boxes |

Delivery Time | 25-30 days |

The Properties of Aluminum Coil For Bottle Cap:

Temper | Thickness mm | Tensile Strength Rm MPa | Yield Strength Rp0.2 MPa | Elongation % A50mm | Bend Radius | Hardness HBWa | |||

H14 | 0.20-0.27 | min. | max. | min. | max. | 180° | 90° | ||

120 | 170 | 110 | 1 | 41 | |||||

H16 | 0.20-0.27 | 160 | 145 | 1 | 50 | ||||

The Advantages of Aluminium Sheet For Bottle Cap:

1. The surface is smooth;

2. No cracks, bubbles or through pores on the surface;

3. No metal and non-metal press-in on the surface;

4. No light and dark stripes on the surface;

5. No burrs, knife back prints or ruffles;

6. No cracks or creases appear in the stamping test.

The Application of Aluminum Sheet For Bottle Cap:

Wine bottle caps, medical caps, cosmetic caps, soft drink/juice/isotonic/energy beverage caps, cosmetic caps, can caps, vial seals caps, tear off seal caps, flip-off vial seals, aluminium closures, pharmaceutical caps, pull-off aluminum cap, injection vial caps, injection bottle caps.

The cap material process has to go through a number of processes such as hot rolling - cold rolling - annealing - dos oil lubrication -coating - printing- slitting - quality check- packaging, etc.

Wine bottle caps, medical caps, cosmetic caps, soft drink/juice/isotonic/energy beverage caps, cosmetic caps, can caps, vial seals caps, tear off seal caps, flip-off vial seals, aluminium closures, pharmaceutical caps, pull-off aluminum cap, injection vial caps, injection bottle caps.

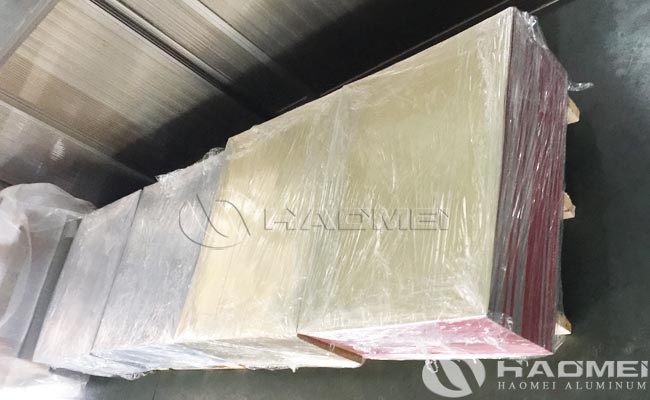

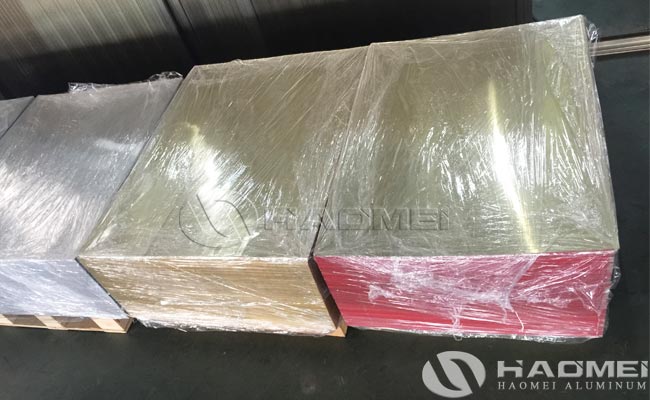

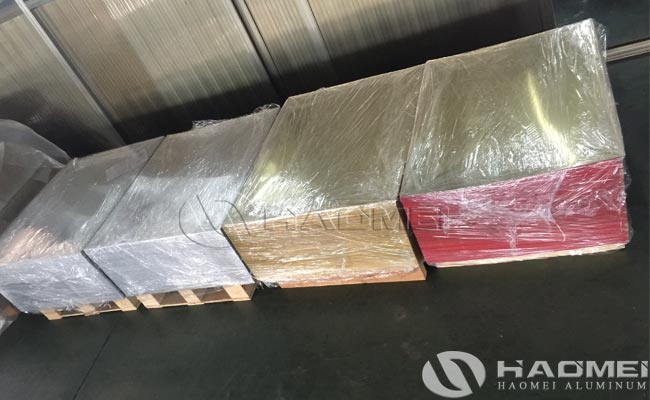

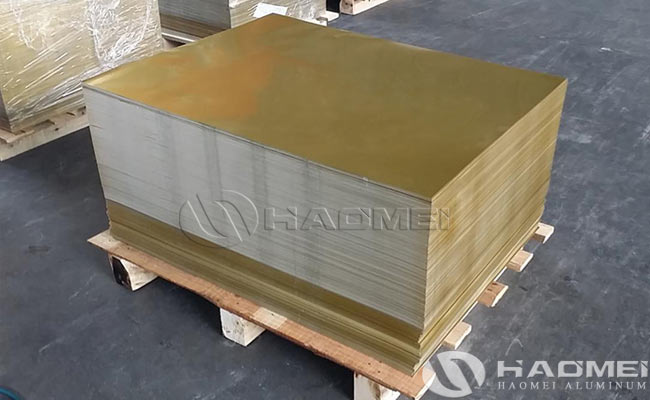

8011/3105 aluminum sheet will be packed by wooden pallet with net weight 0.8-1 ton per each pallet.There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

20’ GP FCL can full-load 20 tons by putting 2 layers of pallets of products.