Chromated Lubricated Aluminium Sheet For Caps

The chromated lubricated aluminium sheet for caps produced by Haomei Aluminum has better coating and anti corrosion performance. The main purpose of chromized treatment of aluminum sheet for caps is to form a chromium film on the surface of the aluminum sheet, which improves the adhesion of the coating during the spraying process. Chromized treatment is a common pre-treatment method for aluminum products, which chemically reacts to form a uniform, dense, and corrosion-resistant chromium film on the surface of the product, enhancing the corrosion resistance of the product and the adhesion of the coating.

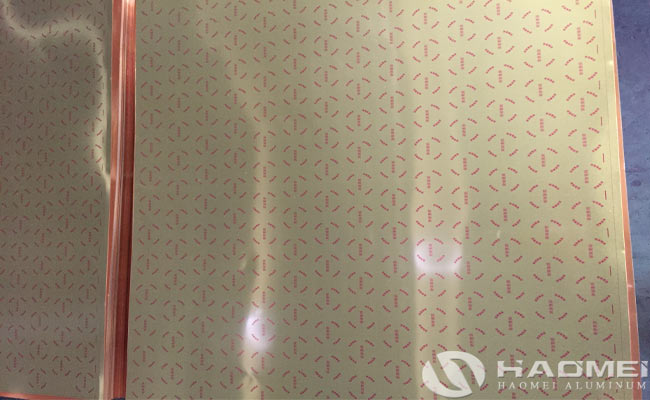

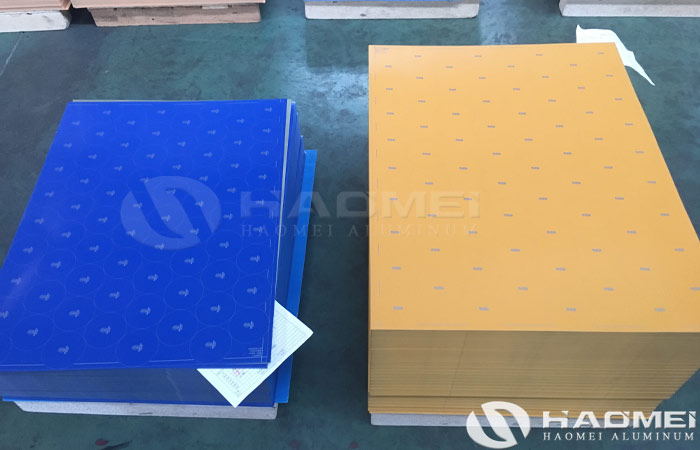

The role of chromium treatment is to improve surface smoothness and enhance surface decoration effects such as coloring and brightness, improve appearance quality, enhance chemical functions such as corrosion resistance, wear resistance, light resistance, and strength, and improve physical functions such as surface hardness, wear resistance, electrical insulation, voltage resistance, static capacitance, heat absorption capacity, and lubrication. The surface of the chromized lubricated aluminum for caps is degreased and cleaned, washed with water, alkaline washed (degreased), washed with water, acid washed, washed with water, chromium treated, washed with water, and rinsed with pure water. Chromized treatment forms a chemically transformed film on the surface of the product, with a film thickness of 0.5-4um. This transformation film has good adsorption and mainly serves as a base layer for coating. The appearance can be gold, natural aluminum color, green, etc.

Haomei Aluminum produces various 1 series, 3 series, 5 series, and 8 series chromated lubricated aluminium sheet for caps products that can be used for bottle cap material production, commonly including 1060 aluminum coil/strip, 3104 aluminum sheet/coil/strip, 3105 aluminum sheet/coil/strip, 5052 aluminum sheet/coil/strip, 1235 aluminum foil, 8011 aluminum foil, etc. Haomei Aluminum is a aluminum sheet strip processing enterprise with an independently developed "1+4" hot rolling production line, integrating precision integrated plate shape and convexity control system, significantly improving product quality.