Haomei Aluminum is a professional 3105/8011 aluminium sheet for closure caps manufacturer in China. To meet diversified and needs of our clients, we also provide DC and CC aluminum closure sheet for PP caps. With good drawing performance, bare possibility of earing and corrosion, the aluminium cap closure sheet that we produce is the ideal material for Pilfer Proof caps, pharmaceutical caps. Applications range from screw caps for whiskey and other beverage bottles to aluminum closures for wine bottles. PP cap aluminum coil material can be ordered as rolled, degreased, pre-lubed, pre-treated and/or lacquered.

The Specification of Aluminum Sheet For Closure Caps:

Alloy | 8011/3105 Aluminum Alloy |

Temper | H14, H16, H18, H24, H26, H44, H46 |

Thickness | 0.15-0.45mm |

Type | Sheet/Coils/Foils/Strips |

Surface Treatment | Aluminum surface is treated by phosphorous chromate and DOS oil treated. |

Application | Caps, closures and vials for the pharmaceutical industry. Closures ‘pilfer proof’ for the pharmaceutical industry. Lids and containers for the cosmetics industry. |

MOQ | 1-3 ton per specification |

Packaging | Export wooden stronger boxes |

Delivery Time | 25-30 days |

The Properties of Aluminum For Closure Caps:

Mechanical Property for CC Materials of Aluminium Sheet for Closure Cap | ||||||

Alloy | Temper | Thickness (mm) | U.T.S (Mpa) | Elongation (%) | Earring Rate | |

8011 | H14 | 0.16~0.23 | 185~205 | >=2 | <2% | |

Mechanical Property for DC Materials of Aluminium Sheet for Closure Cap | ||||||

Alloy | Temper | Thickness (mm) | U.T.S (Mpa) | Elongation (%) | Earring Rate | |

8011 | H14 | 0.16~0.23 | 125~155 | >=2 | <2% | |

Temper | Thickness mm | Tensile Strength Rm MPa | Yield Strength Rp0.2 MPa | Elongation % A50mm | Bend Radius | Hardness HBWa | |||

H14 | 0.20-0.27 | min. | max. | min. | max. | 180° | 90° | ||

120 | 170 | 110 | 1 | 41 | |||||

H16 | 0.20-0.27 | 160 | 145 | 1 | 50 | ||||

The Advantages of Aluminium For Closure Caps:

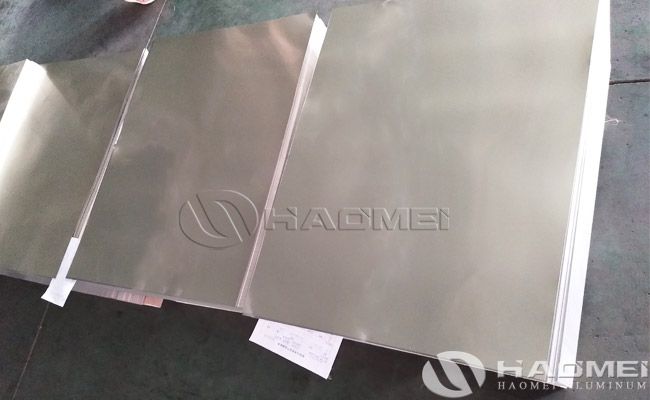

1, The surface is free of any defects including cracks, bubbles, pressing marks, light and dark stripes,etc.

2, The width and thickness tolerance are strictly implemented according to the requirements.

3, Its strength, high formability, low earring and printable surfaces make it ideal for pilfer-proof caps and vial seals.

4, It is applicable for the sealing of alcohol, cosmetics, beverage, especially for long-neck wine bottles.

5, Fine tolerance enables our closure sheet yield more closure per tonne.

6, It is light, bright and economically recycled.

The Application of Aluminium Cap Closure sheet:

Customers use our aluminum sheet to manufacture the caps for long neck wine bottles, plus a range of pilfer proof caps for beverage bottles, soft drinks, juice, isotonic beverage, energy beverage, and other products.

The cap material process has to go through a number of processes such as hot rolling - cold rolling - annealing - dos oil lubrication -coating - printing- slitting - quality check- packaging, etc.

Wine bottle caps, medical caps, cosmetic caps, soft drink/juice/isotonic/energy beverage caps, cosmetic caps, can caps, vial seals caps, tear off seal caps, flip-off vial seals, aluminium closures, pharmaceutical caps, pull-off aluminum cap, injection vial caps, injection bottle caps.

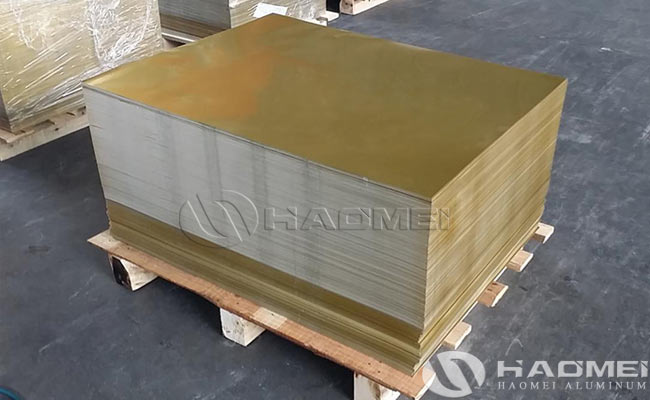

8011/3105 aluminum sheet will be packed by wooden pallet with net weight 0.8-1 ton per each pallet.There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

20’ GP FCL can full-load 20 tons by putting 2 layers of pallets of products.