5182 aluminum for closure pp caps material is one of the options used to produce can end for beverage cans and is suitable for making lids for cans with internal pressure. 5182 aluminum sheet coil DC/CC is known for its excellent formability, good corrosion resistance, light weight and strength, making it an ideal choice for can end.

The Specification of Aluminum For Closure PP Caps DC Material 5182:

| Aluminum | 5182 |

Width | 150-1900mm |

Thickness | 0.2-0.51mm |

Tensile strength | 360-430Mpa |

Yield strength | ≥310~370 Mpa |

Elongation | ≥6% |

Material temper | H48, H19 |

Packing | aluminum coil roll, aluminum strip |

Typical Products | Can end, Can lids and pull ring |

The Performance of Aluminum For PP Caps Material 5182:

Formability.

One of the key properties of 5182 H48 aluminum coil is formability. The aluminum coil can be molded into a variety of shapes without cracking or tearing. This makes it ideal for producing can lid with complex designs.

Corrosion resistance.

5182 H48 aluminum coil has good corrosion resistance. It can be used in solutions with moisture or slight corrosiveness and is often used to make lids for carbonated beverages.

Light weight.

Aluminum is light in weight. This makes it the best choice for producing can end, and the lightweight design helps reduce the overall weight of beverage cans, which can also reduce production costs.

Strength.

Despite its light weight, 5182 H48 aluminum coil is also known for its strength and durability. Aluminum can withstand the stresses and impacts that can occur during use.

The Advantages of Aluminum For closure PP Caps CC Material 5182:

(1) Ring Pull stock generally adopts 5052 5182 aluminum alloy processing, the Ring Pull Can Lid material generally use 5052 and 5182 aluminum alloys processed;

(2) flexible, stamping deformation is not easy to crack;

(3) small density, light weight, smooth surface, feel good;

(4) environmental protection is easy to recycle and reuse.

The application of 5182 Aluminum For PP Caps Material:

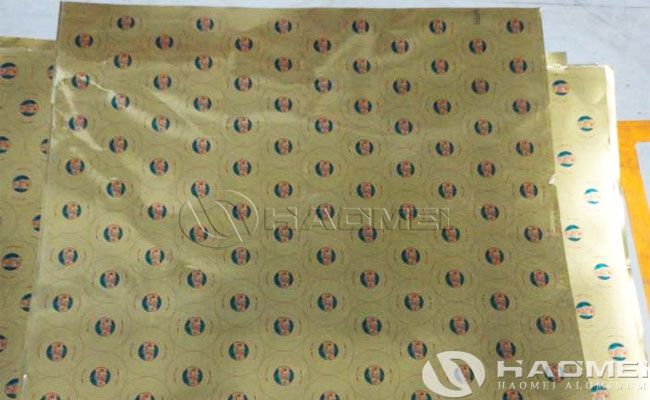

The cap material process has to go through a number of processes such as hot rolling - cold rolling - annealing - dos oil lubrication -coating - printing- slitting - quality check- packaging, etc.

Wine bottle caps, medical caps, cosmetic caps, soft drink/juice/isotonic/energy beverage caps, cosmetic caps, can caps, vial seals caps, tear off seal caps, flip-off vial seals, aluminium closures, pharmaceutical caps, pull-off aluminum cap, injection vial caps, injection bottle caps.

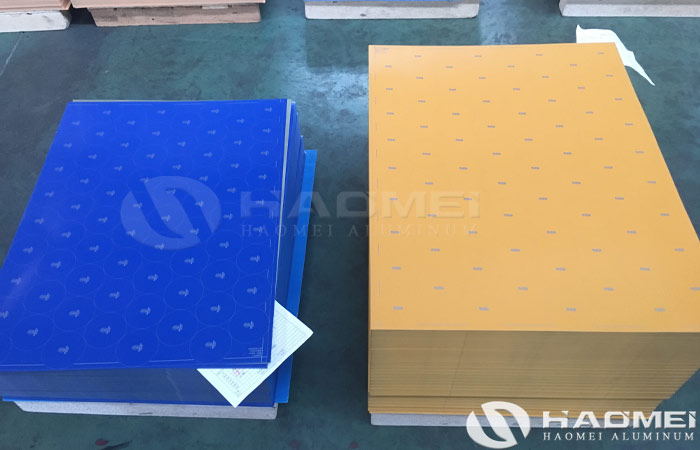

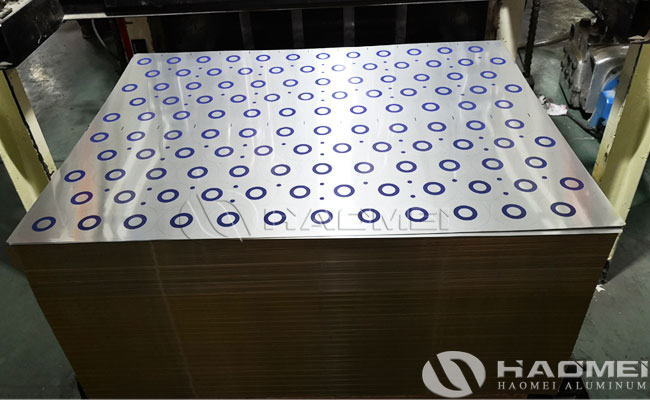

8011/3105 aluminum sheet will be packed by wooden pallet with net weight 0.8-1 ton per each pallet.There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

20’ GP FCL can full-load 20 tons by putting 2 layers of pallets of products.