Aluminum for PP caps closures 3105 have excellent deep-drawing capabilities and lacquer adhesion, making sure the highest quality printing of drawings and designs, giving an impressive finish.

Haomei Aluminum offer Direct Cast and Continuous Cast 3105 aluminium for PP caps closures with high quality and good price, we have export aluminum sheet for pp caps to more than 20 countries, established good cooperative relations with well-known bottle cap manufacturers.

The Specification of Aluminum For PP Caps Closures 3105:

Alloy | 8011/3105 Aluminum Alloy |

Temper | H14, H16, H24, H26, H44, H46 |

Thickness | 0.15-0.45mm |

Type | Sheet/Coils/Foils/Strips |

Surface Treatment | Aluminum surface is treated by phosphorous chromate and DOS oil treated. |

Application | Caps, closures and vials for the pharmaceutical industry. Closures ‘pilfer proof’ for the pharmaceutical industry. Lids and containers for the cosmetics industry. |

MOQ | 1-3 ton per specification |

Packaging | Export wooden stronger boxes |

Delivery Time | 25-30 days |

The Strength of Haomei Aluminium For PP Caps Closures 3105:

1, Internationally advanced "1+4" continuous hot rolling production line with capacity of 200,000 tons.

2, The high-precision integrated plate crown control system greatly improves product quality.

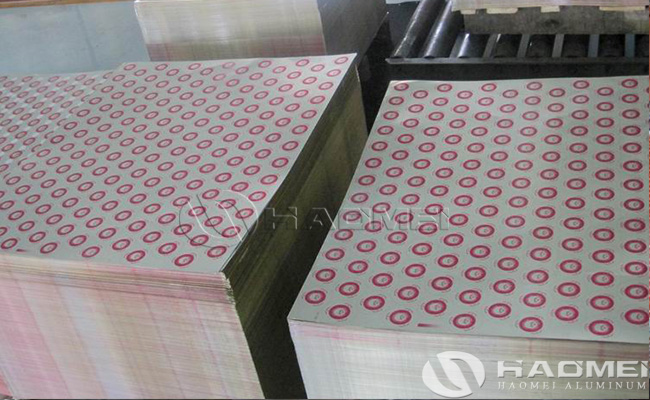

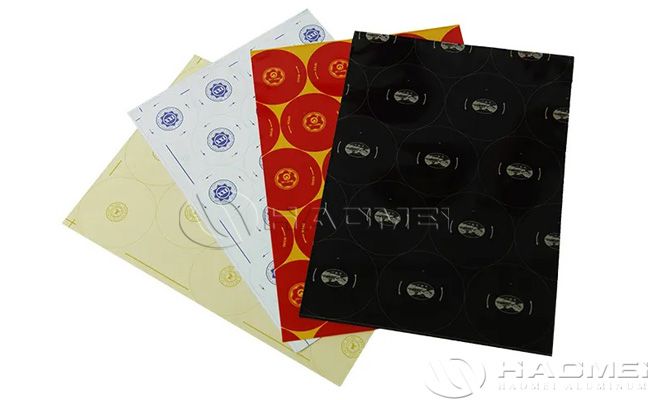

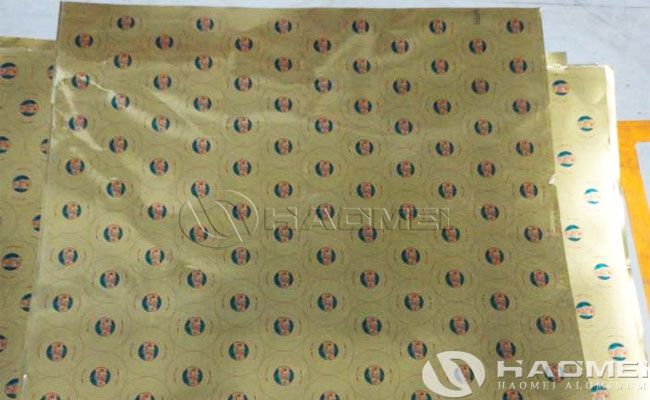

3, Haomei aluminum for closure PP caps 3105 meets various processing requirements, which is suitable for multi-color printing.

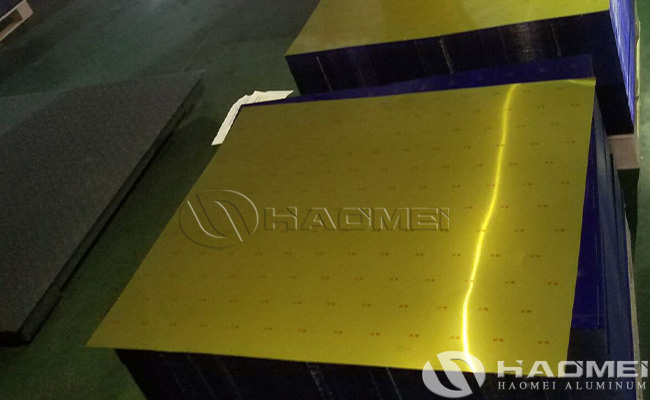

4, Haomei's 3105 aluminium for closures PP caps materials have flat shape, precise geometric dimensions, high surface gloss, and good alkaline washing effects, which can reach level A in the water washing experiment

The Advantages of Aluminum For Closure PP Caps 3105:

1, 3105 H14 H16 aluminum for PP caps closures has good electrical conductivity. Since 0.3% of copper is added to it, the electrical conductivity can reach 41%;

2, 3105 H14 H16 aluminium for PP caps closure has good anti-rust performance. It can be used in various bottle and can caps to achieve long-term and beautiful appearance of the bottle and can;

3, Good processing performance, novel product shape and long service life;

4, Strictly control the processing quality, texture, grain, composition, etc. of the product, and the product performance reaches the international level;

The Application of Aluminium For Closure PP Caps 3105:

Wine bottle caps, medical caps, cosmetic caps, soft drink/juice/isotonic/energy beverage caps, cosmetic caps, can caps, vial seals caps, tear off seal caps, flip-off vial seals, aluminium closures, pharmaceutical caps, pull-off aluminum cap, injection vial caps, injection bottle caps.

The cap material process has to go through a number of processes such as hot rolling - cold rolling - annealing - dos oil lubrication -coating - printing- slitting - quality check- packaging, etc.

Wine bottle caps, medical caps, cosmetic caps, soft drink/juice/isotonic/energy beverage caps, cosmetic caps, can caps, vial seals caps, tear off seal caps, flip-off vial seals, aluminium closures, pharmaceutical caps, pull-off aluminum cap, injection vial caps, injection bottle caps.

8011/3105 aluminum sheet will be packed by wooden pallet with net weight 0.8-1 ton per each pallet.There are styles of packaging, which is eye to wall or eye to sky. Customers can choose either of them for their convenience.

Plastic movie and brown paper can be protected at customers’ need. Also timber case or timber pallet is adopted to shield products from harm for the duration of the delivery.

20’ GP FCL can full-load 20 tons by putting 2 layers of pallets of products.