3105 Aluminum Foil For Closure Caps Manufacturers

Professional 3105 aluminum foil for closure caps manufacturers in China offer aluminum caps materials with deep drawing performance. At present, the cosmetic closure caps on the market are mostly made of plastic and aluminum materials. In comparison, the aluminum material is better in sealing and the closure cap is more beautiful, it is a kind of bottle cap material for many cosmetics. The joint part of the aluminum bottle cap material will come into contact with the liquid in the bottle, so 3105 aluminum foil is often used as the aluminum substrate for cosmetic bottle caps, and the thickness is generally between 0.15mm-0.5mm.

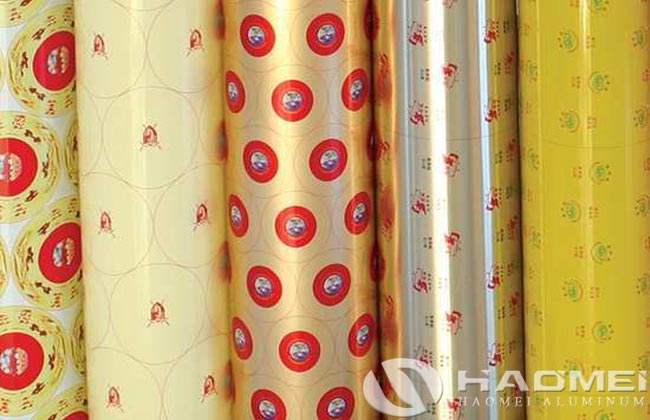

The 3105 aluminum foil for closure caps manufacturers also produce other aluminum alloys for closure caps. The medicinal aluminum bottle cap is made of 8011 aluminum foil, which is mainly used for the closed port of the infusion bottle. Its thickness ranges from 0.018-0.04mm, which has good airtightness. The 5052 aluminum alloy bottle cap material is mainly used for the bottle cap of the pop can , the 5000 series aluminum alloy is added with magnesium, and its hardness is slightly better than other alloys, they are used on cans, which solves the deformation caused by the bumping and pressure of cans during transportation, and ensures the aesthetic appearance of the cans. In addition, the 3105 aluminum foil for closure caps of the 3000 series aluminum alloy is mainly used on cosmetic bottle caps. In addition, the aluminum foil for closure caps manufacturers manufacturer has made great efforts on the appearance, making different shapes, painting bright colors, and meticulously crafted. It is also very good choice for high-end cosmetics.

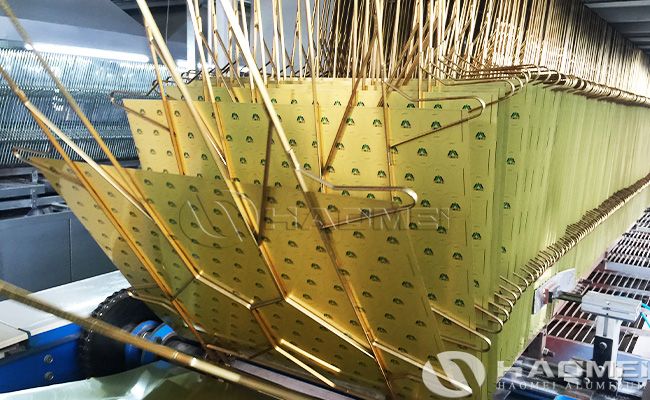

Aluminum bottle caps for cosmetics are mostly processed on a production line with a high degree of automation, so the requirements for the strength, elongation and dimensional deviation of 3105 aluminum foil are very strict, otherwise cracks or creases will occur during processing. In order to ensure that the bottle cap is easy to print after forming, it is required that the surface of the 3105 aluminum foil for closure caps is flat, free of rolling marks, scratches and stains. Due to the high requirements for aluminum bottle cap materials for cosmetics, there are relatively few mature 3105 aluminum foil for closure caps manufacturers in the domestic market. As far as the current market distribution is concerned, Haomei Aluminum has a relatively large market share, occupying more than a half of market share of bottle cap materials, and there is a clear growth trend. With its advantages and good market reputation, it has won the favor of the majority of closure caps manufacturers.