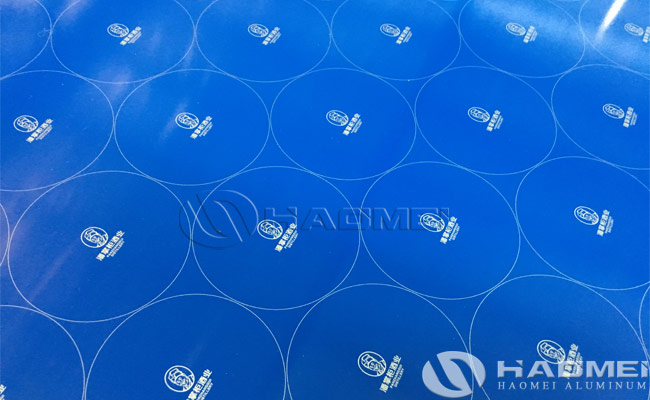

Aluminum For Jar Caps

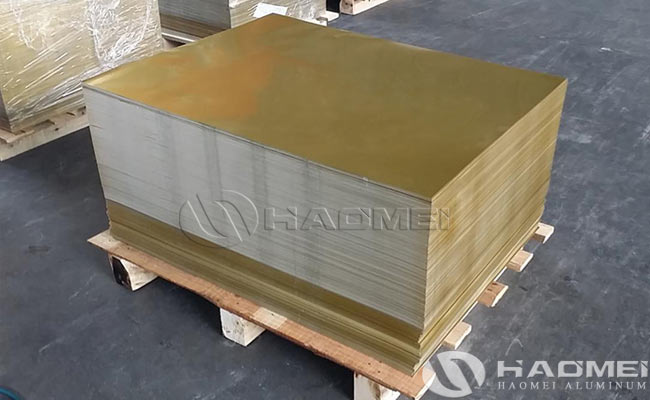

The aluminum jar cap is relatively shallow, and is generally made of one time annealed 8011 cast rolled aluminum. In order to maintain good seal quality, 8011 aluminum strip coil is varnish coated on the inner surface to maintain the perfect combination of the jar cap and the inner plastic pad.

The aluminum caps are usually made of 8011 h16/h14. Aluminum for jar caps can be coated with epoxy varnish on both sides, or painted in different colors. It is usually used for jar caps of food, snacks fruit and beverage.

Property of Aluminum for Jar Caps:

Chemical Composition: Alloy type 8011 H16 According to EN573-3

Size and deviations from the size

| Thickness tolerance | -0+0.5mm |

| Width tolerance | -0+0.5mm |

| Length tolerance | -0+0.5mm |

Deviations of the forms/shapes:

| Deviations of the straight for hardness of the longitudinal border | max 1mm |

| Deviation of flatness | max 4mm |

| Rectangularity: max difference in the diagonals | 3mm |

| Dislocation between the sheets | max 2mm |

Performance index of Aluminium for Jar Caps:

Boiling resistance: The paint does not fall off or change color after boiling at 121 degrees Celsius for half an hour.

Resistant to acetone and mercuric chloride: no obvious color fading after repeated wiping for 20 times.

Tensile strength: 130-155mpa

Elongation: 2.5-3.5 %

Ear control rate: maximum 2%

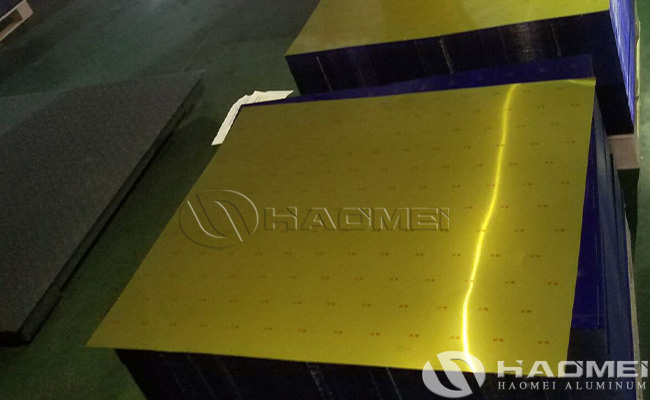

Surface of Aluminum Sheet for Jar Caps:

1. The surface of the aluminum strip or coil for jar caps shall be oil-free, this is controlled by testing with clean natural cotton pads, dipped in 100% distilled water.

2. Droplets, spots caused by corrosion and burnt lubricant on the surface of the sheets not acceptable.

3. Minor scratches and staining not acceptable as well.