Aluminum For Lamp Caps

To make aluminum lamp cap, stamping aluminum strip first and then tapping into spiral shape, thinner aluminum materials need to withstand the pressure. Therefore, the aluminum for lamp caps need to be with high mechanical strength and uniform microstructure and deep drawing property.

Haomei Aluminum use the flat ingot hot rolling for producing 3004 O aluminum strip for lamp caps. To make high quality 3004 O aluminum strip for lamp base, we have to control the composition of the material and cast rolling process, the high temperature uniformity of annealing and final annealing process, it have good deep drawing quality, enough strength, good formability.

Our Aluminium strip for lamp caps materials combines strength and high formability with high resistance to softening in vitriting. Manufactured at modern and well-equipped mills, it can be rolled to very fine tolerances, allowing more caps per tonne of coil and enabling uninterrupted operations of high-speed forming presses.

Specification of Aluminum For Lamp Caps:

| Alloy | 3004 Aluminium Strip |

| Temper | O |

| Thickness | 0.25-0.40mm |

| Width | 80-400mm |

| Surface Treatment | Mill finish |

| Processing | Direct Casting, Hoting Rolling |

| Features | Good for deep drawing,anodizing |

| Application | Lamp Base Industry |

| Place of Origin | Henan, China (Mainland) |

Packing | Export Standard Package, moisture-proof, strong enough, suit for long distance sea transport. Lampcap stock is placed on wooden pallets/case in an eye-to-wall position. |

Chemical Composition

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ga | Ti | Al |

3004 | ≤0.3 | ≤0.7 | ≤0.25 | 1.0-1.5 | 0.8-1.3 | ≤0.05 | ≤0.05 | ≤0.25 | - | ≤0.05 | other |

Mechanical Property

Alloy | Temper | Thickness(mm) | Width(mm) | U.T.S(Mpa) | Yield Strength Rp0.2 MPa | Elongation(%) |

3004 | O | 0.25-0.40 | 85-400 | 155-200 | 60 | ≥13 |

Tolerance

Thickness | Width |

±0.01mm | ±0.5mm |

Advantage of Aluminium For Lamp Caps:

1. 3004 Aluminium is categorized as Wrought Aluminum Alloy. It is composed of (in weight percentage) 97.8% Aluminum (Al), 1.2% Manganese (Mn), and 1.0% Magnesium (Mg).

2. Aluminum is a silverish white metal that has a strong resistance to corrosion and like gold, is rather malleable. It is a relatively light metal compared to metals such as steel, nickel, brass, and copper with a specific gravity of 2.7.

3. Aluminum is easily machinable and can have a wide variety of surface finishes.

4. It also has good electrical and thermal conductivities and is highly reflective to heat and light.

5. The typical elastic modulus of aluminum at room temperature (25°C) ranges from 70 to 79 GPa.

6. The typical density of aluminum alloys ranges from 2.6 to 2.8 g/cm3.

7. The typical tensile strength varies between 230 and 570 MPa. The wide range of ultimate tensile strength is largely due to different heat treatment conditions.

8. 3004 Aluminium is easily formed by either cold or hot working with conventional tooling.

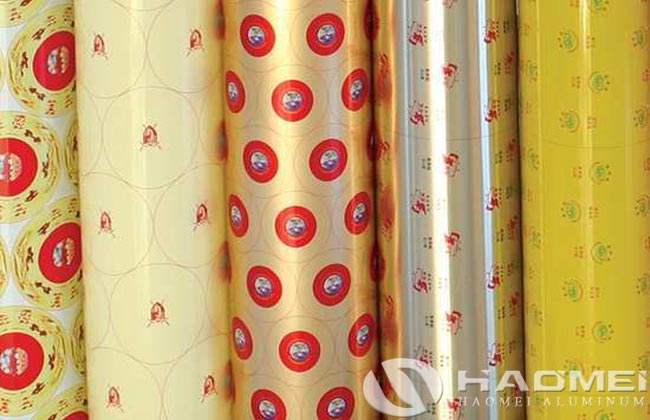

Application of Aluminum For Lamp Base:

Bulb Caps, Tube Caps, Caps of fluorescent tube lights Electrical Sector, etc