Aluminum For Injection Vial Seal

Aluminum vial seals were normally made by 1060 aluminum, then to be anodized so as to protect its surface. However anodizing process shall cause water pollution, then such technology is slowly being phased out.

Haomei Aluminum offer 8011 H16/H14 strip aluminum for vial selas, which is ideal material to make injection vial caps. Nowadays aluminum injection vial seals are normally made by 8011 H16/H14 aluminum, then lacquered by epoxy clear varnish, or lacquered in different colors, normally in yellow color, golden color, red color, blue color and black color.

Specification of Aluminum for Injection Vial:

| Alloy | 8011 H16/H14 |

| Thickness | 0.15-0.30mm |

| Width | 30mm -1000mm |

| Inner diameter | Paper core 76mm, 152mm and 80mm without core. |

| Outer diameter | 500-800mm |

| Packing | Wooden case, wooden pallet if request. |

Surface of aluminium for injection vial:

Both sides clear epoxy varnish.

One side clear epoxy varnish, the other side color coated.

Coating thickness.

Golden color /yellow color: both sides coating 5-6g/m2, one side coating 2-3g/m2.

5. White/red/black/blue color: Both sides coating 10-13g/m2.

Coating quality of Aluminum for Vial seals:

1. Boiling Resistant: Boiling 121 degrees for half an hour, the paint does not fall off, do not change color.

2. Resistance to acetone and mercuric chloride: repeatedly wiping 20 times without significant stripping.

Advantages of Aluminium For Vial Seals:

1: 1000 class cleaning workshop meets the GMP standard.

2: Stable deep drawing quality to make sure highest rates of materials rate.

3: Varnished and color coated surface could be used for cap maker directly.

Application of Aluminum for Injection Vial Seal:

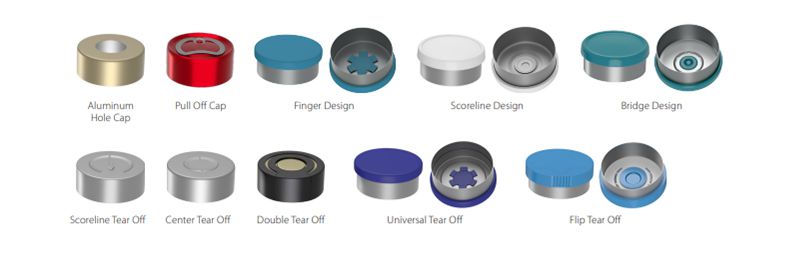

Vial aluminum seals, aluminum tear off seal, aluminum flip-off vial seals, pharmaceutical caps, pull-off aluminum cap, aluminum seal cap for injection vial, vaccine bottle caps, pull ring tear off aluminum caps, pharmaceutical injection vial cap, ring-pull aluminum cap, medicine vial cap.