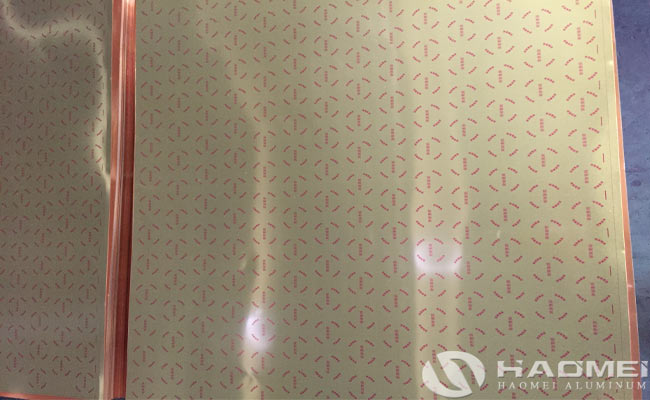

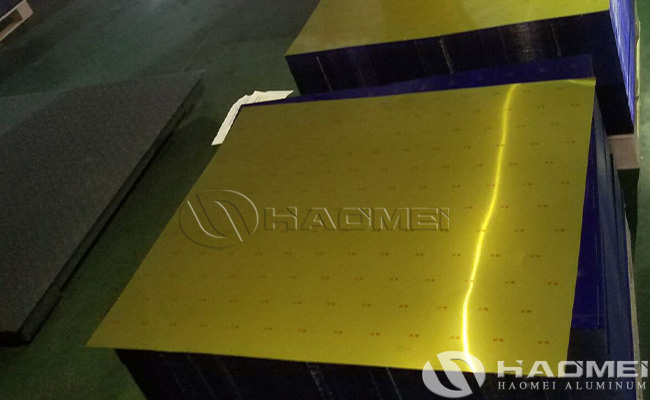

3105 H14 H16 Aluminum Sheet For Screw Cap Closures

3105 aluminum sheet is a commonly used aluminum-magnesium-manganese alloy that is widely used in packaging materials, architectural decorative panels and other fields. Due to its good formability, corrosion resistance and surface treatment properties, 3105 aluminum sheet is also well suited for the manufacture of screw cap closures.

3105 aluminum sheet belongs to the AL-Mn alloy series, which has good rust resistance and electrical conductivity. It contains up to 98% aluminum with 0.3% copper added to enhance its electrical conductivity. This kind of aluminum sheet can not be strengthened by heat treatment, so it is usually used to improve its mechanical properties by cold working methods. 3105 aluminum sheet for screw cap closures usually has a variety of tempers, such as H14, H16, etc., the performance of different states of the material varies:

- H14: partially cold worked after solid solution treatment, with medium hardness and good formability. Suitable for applications requiring good formability and ductility.

- H16: More cold worked after solution treatment, higher hardness but slightly poorer formability. Suitable for applications requiring higher hardness and strength.

Recommended choices:

- 3105 H14 aluminum sheet: If you have a more complex screw cap design that requires good formability and ductility, 3105 H14 is recommended.

- 3105 H16 aluminum sheet: If your screw cap needs higher hardness and strength, and can accept slightly worse formability, it is recommended to choose 3105 H16.

Advantages for 3105 aluminum sheet used for screw cap closures:

- Deep Drawing Properties: Both 3105 H14 and H16 aluminum sheet have good deep drawing properties, which allows them to be easily machined into various shapes of screw caps without significant deformation or breakage.

- Strength and tenacity: 3105 aluminum sheet are moderate in strength, ensuring a tight seal on the screw cap while remaining tough enough to resist breaking when opened.

- Corrosion resistance: 3105 aluminum alloy shows good corrosion resistance in many environmental conditions, suitable for food and beverage packaging.

- Formability: 3105 aluminum sheet has good formability in both H14 and H16 tempers, suitable for screw cap pressing and forming.

- Sealing performance: The properties of the aluminum material itself enable the screw cap to provide good sealing performance to prevent leakage and deterioration of the contents.

- Processing performance: 3105 aluminum sheet is easy to process and handle, which can produce exquisite screw caps with long service life. In addition, its processing costs are relatively low, which is conducive to reducing production costs.

- Food safety performance: Since the aluminum screw cap is in direct contact with food (e.g. wine), the food safety performance is crucial. 3105 aluminum sheet has good cleanliness and hygienic safety, which can ensure the safety of food in the process of storage and transportation.

In summary, both 3105 H14 and H16 aluminum sheets are suitable for screw cap closures, and they excel in strength, toughness, processability and food safety performance.